Roadjunkie1

Well Known Member

I know this has been discussed before but there are a few items that I discovered on my journey to do mine.

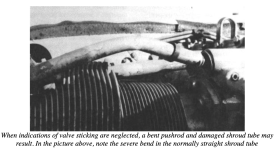

First: this is a Lycoming Mandatory Service Bulletin. Is that actually something that HAS to be done? Or is it just prudent? I think it is most important with a certain group of engines that came from the factory with less than good valve guides but apparently is recommended for all..... Several mechanics I have talked to have said No and one or two asked What's a wobble test?

I think we need to do a survey with three choices: Have you done a wobble test: Yes. No. What's a wobble test? Recommended every 400 hours on fixed wing, 300 hours on helicopters. Or is it just done with "morning sickness" or suspected valve sticking?

I have messed with valves and valve springs for several decades and never look forward to using the typical prybar mechanisms that are most commonly used. I'm usually working alone and to get the retaining keys out, the springs out and then reverse all that, especially getting the keys back in without dropping them on the hangar floor! All while keeping the springs compressed with one hand or your chest/stomach.....

All while keeping the springs compressed with one hand or your chest/stomach.....

Enter Stage Left: The Valve Wizard. Having heard good things, I decided I needed to try one out. A bit expensive but at what cost convenience and ease of use? I bolted mine on and the rest of the work on the valve and springs was child's play! The springs stay compressed (keeping the valve closed with the Rope Trick) with no effort while the keys are easily fished out. Yes, one has to take the tool off to do what is next but that is a minor inconvenience. Then, reversing all that and compressing the springs to put the keys back in (I still dropped one that quickly disappeared. Oh: there it is! How did it get under the Cub tail?) made that job much easier! Highly recommended! I believe it is 3D printed but is h***-for-stout and handles the job without a whimper.

The Wobble Test Tool: I have seen multiple designs including the Aircraft Spruce design (which doesn't seem to aim at the extension at 90 degrees....and is always on backorder anyway) and wasn't happy with what I was seeing. Some did not conform to what the SB was recommending, like where the reading on the extension should be taken. I wasn't too excited about buying one anyway. So I designed my own loosely referring to the Lycoming SB (one of their dimensions was wrong, BTW) and other designs I had seen. I came up with one that was a minor PTA to make but works very well. The extension I made was from a 3.5 inch length of steel tubing, which also works very well. The acceptable limits (0.013"-0.035") are in the SB and Cylinder #2 was well within that: 0.017". On to the other three!

Have you done yours yet? Have FUN!

Photos: The Tool. Holes in the main body were purposely oval to allow for side-to-side adjustments to center the dial probe on the extension. The Tool at work. The Valve Wizard at work....notice the rope handing off to the side....

First: this is a Lycoming Mandatory Service Bulletin. Is that actually something that HAS to be done? Or is it just prudent? I think it is most important with a certain group of engines that came from the factory with less than good valve guides but apparently is recommended for all..... Several mechanics I have talked to have said No and one or two asked What's a wobble test?

I think we need to do a survey with three choices: Have you done a wobble test: Yes. No. What's a wobble test? Recommended every 400 hours on fixed wing, 300 hours on helicopters. Or is it just done with "morning sickness" or suspected valve sticking?

I have messed with valves and valve springs for several decades and never look forward to using the typical prybar mechanisms that are most commonly used. I'm usually working alone and to get the retaining keys out, the springs out and then reverse all that, especially getting the keys back in without dropping them on the hangar floor!

Enter Stage Left: The Valve Wizard. Having heard good things, I decided I needed to try one out. A bit expensive but at what cost convenience and ease of use? I bolted mine on and the rest of the work on the valve and springs was child's play! The springs stay compressed (keeping the valve closed with the Rope Trick) with no effort while the keys are easily fished out. Yes, one has to take the tool off to do what is next but that is a minor inconvenience. Then, reversing all that and compressing the springs to put the keys back in (I still dropped one that quickly disappeared. Oh: there it is! How did it get under the Cub tail?) made that job much easier! Highly recommended! I believe it is 3D printed but is h***-for-stout and handles the job without a whimper.

The Wobble Test Tool: I have seen multiple designs including the Aircraft Spruce design (which doesn't seem to aim at the extension at 90 degrees....and is always on backorder anyway) and wasn't happy with what I was seeing. Some did not conform to what the SB was recommending, like where the reading on the extension should be taken. I wasn't too excited about buying one anyway. So I designed my own loosely referring to the Lycoming SB (one of their dimensions was wrong, BTW) and other designs I had seen. I came up with one that was a minor PTA to make but works very well. The extension I made was from a 3.5 inch length of steel tubing, which also works very well. The acceptable limits (0.013"-0.035") are in the SB and Cylinder #2 was well within that: 0.017". On to the other three!

Have you done yours yet? Have FUN!

Photos: The Tool. Holes in the main body were purposely oval to allow for side-to-side adjustments to center the dial probe on the extension. The Tool at work. The Valve Wizard at work....notice the rope handing off to the side....