wirejock

Well Known Member

Question. What can be used to mark a wire like a stripe?

This may be genius or foolish. Personally, I think it's pretty genius. Two harnesses were much longer than necessary. ADAHRS & GPS. All have unique colors except one orange common to both. Hence the question. Since the Advanced Control Module switches just connect to ground, the two bundles are perfect for a switch harness. Correct number of wires too! However, I need to differentiate one orange wire so it's unique.

Will magic marker work or will it come off? How about black rattle can primer? I can use a q-tip and drag the wire over it.

Ideas please.

Edit...

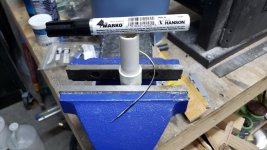

Looks like I can use permenant marker and make a tool like this.

This may be genius or foolish. Personally, I think it's pretty genius. Two harnesses were much longer than necessary. ADAHRS & GPS. All have unique colors except one orange common to both. Hence the question. Since the Advanced Control Module switches just connect to ground, the two bundles are perfect for a switch harness. Correct number of wires too! However, I need to differentiate one orange wire so it's unique.

Will magic marker work or will it come off? How about black rattle can primer? I can use a q-tip and drag the wire over it.

Ideas please.

Edit...

Looks like I can use permenant marker and make a tool like this.

Last edited: