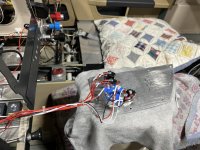

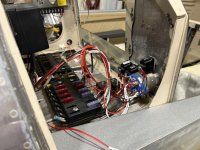

Finally. But, I changed out the Pmag test buttons for Honeywell TLs. And, I moved them. So, I had to fabricate another port side panel. But, I like this way better.

The buttons I was thinking of using made me nervous. The connections are #2 screws and tiny little connectors. Compare to the Honeywells below

Buttons are these:

The previous panel had the buttons too close to the heater knob, also. So, I moved things around a bit and fabbed a new port panel.

The new arrangement separates things a bit better, I think.

Wires are long enough to allow maintenance

The only question I have is:

what is the accepted method of keeping the loop of wires tidy behind the panel when installed?

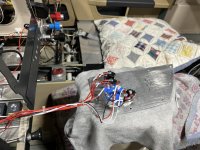

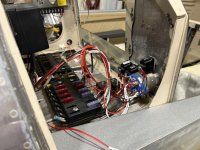

The buttons I was thinking of using made me nervous. The connections are #2 screws and tiny little connectors. Compare to the Honeywells below

Buttons are these:

The previous panel had the buttons too close to the heater knob, also. So, I moved things around a bit and fabbed a new port panel.

The new arrangement separates things a bit better, I think.

Wires are long enough to allow maintenance

The only question I have is:

what is the accepted method of keeping the loop of wires tidy behind the panel when installed?