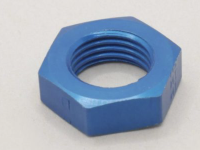

I'm on page 31-08 (fuselage fuel system) where the plans call for us to "fully tighten the AN924-6D nuts on the outboard elbow fittings". The elbow is shown below. Should we use thread locker on those nuts? The plans don't mention it and there is no mention of it in the Wiki but it seems like we wouldn't want that nut to come loose.