macrafic

Well Known Member

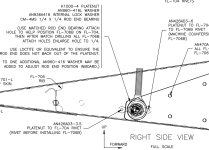

I recently watched Vic Syracuse's presentation on buying an RV (and what to look for). I made a mental note to check my rod end bearings to validate that I installed large washers to prevent the bearing from coming completely detached. My question is about the rod end bearings on the flaps.

They are already pre-assembled (press fit) and there is no way to get a preventative washer on them. I would imagine it would be quite an exciting adventure to be flying along and have one flap bearing detach (asymmetrical flaps!!!!). Has anybody heard of that particular bearing coming apart? Anybody do anything at all to add to its security? Is this me overthinking/over concerned?

They are already pre-assembled (press fit) and there is no way to get a preventative washer on them. I would imagine it would be quite an exciting adventure to be flying along and have one flap bearing detach (asymmetrical flaps!!!!). Has anybody heard of that particular bearing coming apart? Anybody do anything at all to add to its security? Is this me overthinking/over concerned?