I will be installing a GTN 750xi and GMC507 (autopilot controller) in the radio stack of my RV-8 panel. I'm currently designing the panel in Solidworks. I want the mounting trays to be behind the panel and want the bezel of the devices to cover any gaps between the radio stack cutout and the equipment.

Based on the Garmin installation manuals and what I was able to find in old posts, the recommended cutout width for the radio stack is 6.25". But measuring the equipment bezel width in Solidworks, I see that it is also 6.25". So there's no room for tolerance in the cut if I want to hide the gaps.

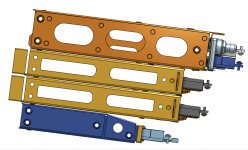

My question is whether any of you guys have experience reducing the width of the radio stack cutout to say 6.18" so that the bezel will definitely cover the gap. I assume the tabs on the side of the GMC507 in the attached picture can be pushed in to fit the equipment all the way in?

Based on the Garmin installation manuals and what I was able to find in old posts, the recommended cutout width for the radio stack is 6.25". But measuring the equipment bezel width in Solidworks, I see that it is also 6.25". So there's no room for tolerance in the cut if I want to hide the gaps.

My question is whether any of you guys have experience reducing the width of the radio stack cutout to say 6.18" so that the bezel will definitely cover the gap. I assume the tabs on the side of the GMC507 in the attached picture can be pushed in to fit the equipment all the way in?