I suck at composites.

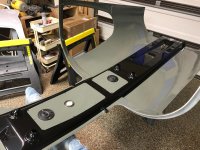

Trying to top coat some fiberglass. Getting tons of pinholes/microbubbles/whatever

The parts are clean. No doubt. It would seem that between the resin surface tension and my brush technique, I’ve got no chance.

Any way to thin the resin? Better application tools? Any advice, web link, video link, etc. would be greatly appreciated. Thanks.

Trying to top coat some fiberglass. Getting tons of pinholes/microbubbles/whatever

The parts are clean. No doubt. It would seem that between the resin surface tension and my brush technique, I’ve got no chance.

Any way to thin the resin? Better application tools? Any advice, web link, video link, etc. would be greatly appreciated. Thanks.