I discovered a tiny leak on my pre-flight to Oshkosh this year. It was such a small amount, I couldn't be sure if it was condensation or antifreeze. It felt a little slippery like antifreeze, but it wasn't enough to be sure. I launched anyway.. figuring this leak had probably existed for many hours previously ..but was simply undiscovered until now. I was checking the fluid levels at each stop though - I didn't find a cause for grounding or to turn back. I did note that my coolant reserve level was 1/8" low at the last annual -- but I chalked it up to internal leaks, evaporation, etc.

I ordered a replacement this weekend with 2-day shipping. Since OSH, the leak is more apparent.. so I'm under self-imposed grounding for now -- though I'd feel comfortable flying within a 5-10 minute radius of an airport now (pattern work).

I think this radiator issue is starting to come up to a level that may warrant factory investigation. I have 490 hours and am still on the original fill of Prestone Extended Life DEXCOOL 50/50 pre-mix (as recommended by Rotax SI-912i-001R8). There've been many others with radiator leaks so far:

- aobrien5

- WJaviation

- Giving_Wings

- mikefox

- bobg56

- Amadeus

- Bob Y

- Reilly (twice)

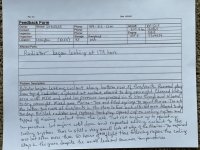

The photo is showing the lowermost cooling fin row, forward facing side, about 2 inches from the copilot-side edge of the fins