Freemasm

Well Known Member

Contributor 74-07 started a post regarding a failed cylinder stud(s) found during unrelated maintenance on his aircraft. That thread can be found here:

https://vansairforce.net/community/showthread.php?t=216725

It seemed better to start this thread here (Edit = I had put this in the General Discussion Thread but they moved it here) versus having it buried in the Traditional Aircraft Engines Forum. (Edit = they moved the thread here, oh well I tried). I hopefully don't need to mention how unlikely this discovery was and how bad this could have otherwise turned out.

The fracture surface of one of the studs was inspected by a well respected, very experienced NDE in a world class materials lab; name and company name are withheld. Can't get him in trouble. He's done favors for us before and I'd hope this can continue. Hopefully this is appreciated by the community here as much as I do.

There are zero surprises here but I'd share the "results" of his expert personal opinion below.

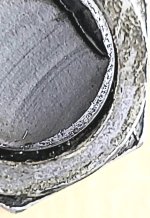

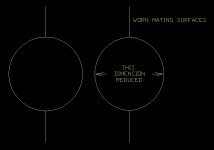

Good morning, xxxx. I received your fractured cylinder hold down stud. Stereo microscope examinations at 8X-40X revealed fracture features consistent with fatigue, initiating at a thread root on one side. I couldn’t see any obvious material defects. I can’t tell you much about any potential contributing factors such as microstructure, material properties, thread conditions, amount of preload, etc. I assume....

Down side = it wasn't challenging enough to get examined by the Scanning Electron Microscope or other cool toys at their disposal so no ultra cool pix. There are some images attached below. Hopefully the system here doesn't rotate them. You can at least see where the fatigue cracking started and the direction it propagated. Excuse the limited file size but it's necessary.

Anyway while no surprises, this does reinforce something I've been harping on a for a while here. There appears to be healthy design margins on our aircraft designs but some areas apparently way less than others. While we can't determine the root cause as to why the studs didn't get (or lost) proper preload, the NDE's short summary does not suggest a material issue.

Cylinder installation continues to demonstrate this application is less tolerant of f--kage than other things in our builds. Records suggest this installation was done by an overhaul shop versus a field install. Follow the OEM instructions. It's important.

Cheers boys

https://vansairforce.net/community/showthread.php?t=216725

It seemed better to start this thread here (Edit = I had put this in the General Discussion Thread but they moved it here) versus having it buried in the Traditional Aircraft Engines Forum. (Edit = they moved the thread here, oh well I tried). I hopefully don't need to mention how unlikely this discovery was and how bad this could have otherwise turned out.

The fracture surface of one of the studs was inspected by a well respected, very experienced NDE in a world class materials lab; name and company name are withheld. Can't get him in trouble. He's done favors for us before and I'd hope this can continue. Hopefully this is appreciated by the community here as much as I do.

There are zero surprises here but I'd share the "results" of his expert personal opinion below.

Good morning, xxxx. I received your fractured cylinder hold down stud. Stereo microscope examinations at 8X-40X revealed fracture features consistent with fatigue, initiating at a thread root on one side. I couldn’t see any obvious material defects. I can’t tell you much about any potential contributing factors such as microstructure, material properties, thread conditions, amount of preload, etc. I assume....

Down side = it wasn't challenging enough to get examined by the Scanning Electron Microscope or other cool toys at their disposal so no ultra cool pix. There are some images attached below. Hopefully the system here doesn't rotate them. You can at least see where the fatigue cracking started and the direction it propagated. Excuse the limited file size but it's necessary.

Anyway while no surprises, this does reinforce something I've been harping on a for a while here. There appears to be healthy design margins on our aircraft designs but some areas apparently way less than others. While we can't determine the root cause as to why the studs didn't get (or lost) proper preload, the NDE's short summary does not suggest a material issue.

Cylinder installation continues to demonstrate this application is less tolerant of f--kage than other things in our builds. Records suggest this installation was done by an overhaul shop versus a field install. Follow the OEM instructions. It's important.

Cheers boys

Attachments

Last edited: