Introducing our newest all-in-one Landing and Taxi light, the Flyleds Tail Dragger Max.

Typically tail dragger aircraft align one light straight ahead for landing and the other light downwards for taxiing. Given how poor to average those lights usually are, and only having one light useful to you in each phase of landing, it's no wonder that night landings are not the most pleasant experience for many.

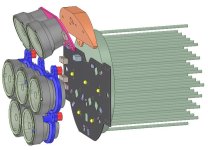

The Flyleds Combo light was introduced in 2018 and it completely changed that experience for hundreds of our customers. Now, based on our highly regarded Seven Stars light, the Tail Dragger Max has the top two light modules aimed 20° downwards (fixed). You get 6500 lumens of clear white light aimed straight ahead in a tight beam for landing, plus another 2500 lumens of light aimed lower, closer and wider, so that you can still see where you're going when the tail is on the ground.

In comparison your average 50 watt halogen headlight fitted to so many RV's is a poorly formed beam of yellow light around 500-700 lumens.

Just the landing light section alone of the Tail Dragger Max light is 8-10 times, or double, then double, then double again (plus a bit more!), the amount of light.

Stop and think about that for a second!

The Tail Dragger Max has two power inputs. The Main input lights up all seven light modules for 7-8 amps draw, while the second (optional) Taxi input turns on just the top two lights at ~2 amps draw. High beams/low beams if you like!

Designed to fit a PAR36 mounting hole in your leading edges. It will drop right into your RV-14 light bay onto the W-00017 bracket supplied as part of the wing kit. It will fit into the various Van's and Duckworks light bays found on other RVs as well, not to mention your Cub etc... If you have rectangular halogens in your leading edges now it's usually just four screws to remove the bracket from your wings and you can enlarge the hole out on the bench in minutes.

The best landing light available that is specifically designed for your tail dragger aircraft. There's nothing else on the market like it!

Typically tail dragger aircraft align one light straight ahead for landing and the other light downwards for taxiing. Given how poor to average those lights usually are, and only having one light useful to you in each phase of landing, it's no wonder that night landings are not the most pleasant experience for many.

The Flyleds Combo light was introduced in 2018 and it completely changed that experience for hundreds of our customers. Now, based on our highly regarded Seven Stars light, the Tail Dragger Max has the top two light modules aimed 20° downwards (fixed). You get 6500 lumens of clear white light aimed straight ahead in a tight beam for landing, plus another 2500 lumens of light aimed lower, closer and wider, so that you can still see where you're going when the tail is on the ground.

In comparison your average 50 watt halogen headlight fitted to so many RV's is a poorly formed beam of yellow light around 500-700 lumens.

Just the landing light section alone of the Tail Dragger Max light is 8-10 times, or double, then double, then double again (plus a bit more!), the amount of light.

Stop and think about that for a second!

The Tail Dragger Max has two power inputs. The Main input lights up all seven light modules for 7-8 amps draw, while the second (optional) Taxi input turns on just the top two lights at ~2 amps draw. High beams/low beams if you like!

Designed to fit a PAR36 mounting hole in your leading edges. It will drop right into your RV-14 light bay onto the W-00017 bracket supplied as part of the wing kit. It will fit into the various Van's and Duckworks light bays found on other RVs as well, not to mention your Cub etc... If you have rectangular halogens in your leading edges now it's usually just four screws to remove the bracket from your wings and you can enlarge the hole out on the bench in minutes.

The best landing light available that is specifically designed for your tail dragger aircraft. There's nothing else on the market like it!