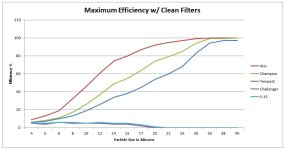

Consider this detail: the previously posted efficiency values (post #1) are the

average for the entire test from beginning to termination at 10 psi deltaP. Performance declines as the filter loads with increasing amounts of test dust, which drags down the average. All of the depth media filters performed better early in the test.

As a practical matter, it means any of the three does a reasonable job if changed before they can load up with a lot of contamination material. We typically change at 50 hours or less, when most engines will have deposited very little material in the filter. You could probably run a filter 200 hours if willing to accept reduced efficiency as the filter loaded with more metals, silica, and carbon.

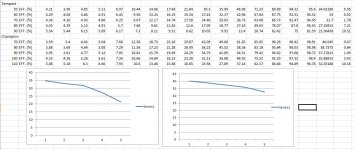

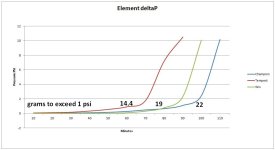

Here's hard data, in two formats, (a) comparison at 10, 30, and 60 minutes into the test, and (b), each filter at 10, 30, and 60.

Yes, there are differences in performance. However, before running out to grab a Wix 51515, note there are other very important factors in a filter decision, like bypass valve opening pressure and enclosure burst pressure. This chart only looks at filtration.

View attachment 60647