Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Erratic fuel pressure . . . that gets better

- Thread starter cdeggz

- Start date

johnpaul44

Member

Vapor lock? Vapor going through the lines makes the fuel pressure oscillate .. after flying for a certain amount of time everything is cooled down and Vapor bubbles go away ?

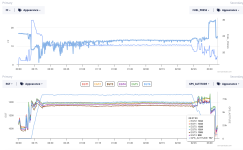

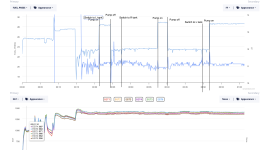

I have been having erratic fuel pressure, but it slowly gets better after an hour of cruise. If I shut down the engine and let the plane sit 2 hours and go fly again, the pattern repeats. Anybody have any theories?

My only thought as well.Vapor lock? Vapor going through the lines makes the fuel pressure oscillate .. after flying for a certain amount of time everything is cooled down and Vapor bubbles go away ?

What kind of fuel system do you have? Where is the FP sensor relative to primary pump? Does the issue go away when the boost pump is turned on? etc.

MacCool

Well Known Member

When I had erratic fuel pressures as you describe, it turned out to be a pinhole leak in the diaphragm of my engine-driven fuel pump, which became apparent after the thing stopped pumping effectively trying to leave a small Iowa airport. Hard to guess what's happening to yours without knowing anything about your hardware.

What sensor do you have?

bpattonsoa

Well Known Member

I had the same in my -10 when the tanks were filled with ground temperatures over 100 F and sat until late afternoon. There was an inversion and it got hotter until about 5,000’. Turned fuel pump off when prop was pulled to climb rpm. Got a low fuel pressure alarm at 17 psi, turned pump back on for the climb to 13.5k and then off. Pressure was erratic, 25 to 20 for about 15 minutes then appeared normal For rest of flight, 4.5 hours. Looking at the graph the pressure wiggled around for about an hour. Air temperature at altitude was normal and the fuel cooled off.I have been having erratic fuel pressure, but it slowly gets better after an hour of cruise. If I shut down the engine and let the plane sit 2 hours and go fly again, the pattern repeats. Anybody have any theories?

Clearly heat related vaporization of the fuel. Now the pump stays on when fuel is hot. Added a air shroud to the engine pump and never saw it again.

Hey Airguy,That's a classic signal of hot fuel causing vapor bubbles at the pump inlet, and at altitude the fuel cools down and stops making vapor bubbles.

I see this as well after refueling from underground tanks on a cool day, but I guess that is still warmer than temperatures at altitude. If this were the case I would assume turning on the boost pump would make it go away?

Fuel system:My only thought as well.

What kind of fuel system do you have? Where is the FP sensor relative to primary pump? Does the issue go away when the boost pump is turned on? etc.

Tanks, filter, boost pump, engine driven pump, fuel injection

I don't recall if the pressure sensor is before or after the engine driven fuel pump. I will take a look and get back to you.

Also a good question on the boost pump. I should be able to collect that data this weekend and get back to you.

Last edited:

I wonder if this could still happen on a 50-degree day and go away up at freezing temperatures aloft (which was my case). Although if that were the case I would expect much worse perforce on a hot day.I had the same in my -10 when the tanks were filled with ground temperatures over 100 F and sat until late afternoon. There was an inversion and it got hotter until about 5,000’. Turned fuel pump off when prop was pulled to climb rpm. Got a low fuel pressure alarm at 17 psi, turned pump back on for the climb to 13.5k and then off. Pressure was erratic, 25 to 20 for about 15 minutes then appeared normal For rest of flight, 4.5 hours. Looking at the graph the pressure wiggled around for about an hour. Air temperature at altitude was normal and the fuel cooled off.

Clearly heat related vaporization of the fuel. Now the pump stays on when fuel is hot. Added a air shroud to the engine pump and never saw it again.

Not sure Vic, I’ll have to check. Are there any that are problematic other than the kavlicos?What sensor do you have?

Pretty much a "standard" mech FI system. Pressure would be measured after the main pump or it would show a vacuum with the boost off.Fuel system:

Tanks, filter, boost pump, engine driven pump, fuel injection

I don't recall if the pressure sensor is before or after the engine driven fuel pump. I will take a look and get back to you.

Also a good question on the boost pump. I should be able to collect that data this weekend and get back to you.

The effects with boost pump in operation will be telling.

AVgas or non-aviation fuel? Probably still in the winter blend months.

OK, duh, I should have realized thatPretty much a "standard" mech FI system. Pressure would be measured after the main pump or it would show a vacuum with the boost off.

100LLThe effects with boost pump in operation will be telling.

AVgas or non-aviation fuel? Probably still in the winter blend months.

Last edited:

Walt, I'm leaning toward this being more of a sensing issue. I would think (maybe I'm wrong) the such a large variation in fuel pressure in cruise would also show up in the EGTs too if there was actual fuel variation. I would love to hear counterpoints to this though.I suggest you fix it before you fly anymore, fuel pressure is pretty important.

Maybe it's indication, or maybe it's not!

I'd like to postulate another theory: After shutdown a lot of vapor from the hot engine heating the fuel lines goes into the hose that goes up to the pressure sensor, even though the air in the line to the engine is cleared out. Due to the orientation of the hose it is trapped there. The fuel in that line combined with the compressible vapor acts as a mass on an air (vapor) spring and bounces around in turbulence causing pressure variation. As the cool fuel and fuel pressure slowly condenses the vapor in that line the spring (vapor) gets smaller and smaller until this issues goes away.

If that were the case then I would expect to see changes in the fuel flow and EGT too though, so maybe not.

I have noticed that if I make a small change on the mixture lever, the fuel flow bounces around a lot for while, which would support this theory.

If that were the case then I would expect to see changes in the fuel flow and EGT too though, so maybe not.

I have noticed that if I make a small change on the mixture lever, the fuel flow bounces around a lot for while, which would support this theory.

RV8JD

Well Known Member

Not that it's causing your problem, but are those the Kavlico pressure transducers that may leak and are subject to these SBs?

From Van's:

SB-00006 - Van's Aircraft Total Performance RV Kit Planes

Potential leaking of Kavlico pressure sensors

From Dynon:

From Garmin:

Legacy Kavlico sensor:

Updated Kavlico sensor:

Last edited:

Walt

Well Known Member

At lower power settings, the servo will work normally down to around 17-18 psi and FF would remain unchanged. Anything less than that and you'll start having problems. Everyone wants to point to sensing first because that the easiest thing to 'fix' and you keep flying the aircraft. If the pressure all over the place (you have good Kavlico sensors so doubt that's the problem), I tend to suspect fuel system problems first until proven otherwise.Walt, I'm leaning toward this being more of a sensing issue. I would think (maybe I'm wrong) the such a large variation in fuel pressure in cruise would also show up in the EGTs too if there was actual fuel variation. I would love to hear counterpoints to this though.

And as far as theories about trapped air, nonsense.

Yes I think they are. That is on my to do list for the next CI. I did not get to it this year.Not that it's causing your problem, but are those the Kavlico pressure transducers that may leak and are subject to these SBs?

From Van's:

SB-00006 - Van's Aircraft Total Performance RV Kit Planes

Potential leaking of Kavlico pressure sensorswww.vansaircraft.com

From Dynon:

From Garmin:

Legacy Kavlico sensor:Updated Kavlico sensor:

Can you expand on this? I'd like to learn why.And as far as theories about trapped air, nonsense.

With those sensors I don’t think you have a sensing problem. That’s why I asked that question first. Looking at your data, you could have a leak somewhere that is allowing it to suck air, or a failing pump. Next steps: verify it does the same when feeding from both tanks. See if there is any change with boost pump on or off.

Just to clarify, you can't necessarily judge visually whether you have an old Kavlico sensor based on appearance alone. I agree that updated sensors which look like the bottom image are available, but one of the approved replacements is the Kavlico P4055-5020 series, which is visually the same as the top image. You have to look at the markings to be sure.

Dynon switched from the Sensata/Kavlico P4055-5020 to the P255 series.Just to clarify, you can't necessarily judge visually whether you have an old Kavlico sensor based on appearance alone. I agree that updated sensors which look like the bottom image are available, but one of the approved replacements is the Kavlico P4055-5020 series, which is visually the same as the top image. You have to look at the markings to be sure.

I haven’t read the entire thread so I don’t know if anyone has suggested these these or not.

1) makes sure your vents are fully clear. They could have a slight obstruction that may cause fluctuations especially at high flow rates

2) I’d change the fuel filter. I recently had a situation where my filter was causing just enough restriction that my fuel pressure dropped off at high power but not low power.

Like Vic said. Fix it. Don’t assume just an indication

1) makes sure your vents are fully clear. They could have a slight obstruction that may cause fluctuations especially at high flow rates

2) I’d change the fuel filter. I recently had a situation where my filter was causing just enough restriction that my fuel pressure dropped off at high power but not low power.

Like Vic said. Fix it. Don’t assume just an indication

I'm not the builder, so I'm not exactly sure. They go to a Dynon/AFS EMS. What are you getting to here? Wire gauge concerns?What did you use to connect the three sensor wires (Red/Green/Black) to the wiring to the GEA 24?

Connection integrity - are the wires spliced, crimped, chewing gummed, etc.?I'm not the builder, so I'm not exactly sure. They go to a Dynon/AFS EMS. What are you getting to here? Wire gauge concerns?

Thanks flyfish.I haven’t read the entire thread so I don’t know if anyone has suggested these these or not.

1) makes sure your vents are fully clear. They could have a slight obstruction that may cause fluctuations especially at high flow rates

2) I’d change the fuel filter. I recently had a situation where my filter was causing just enough restriction that my fuel pressure dropped off at high power but not low power.

Like Vic said. Fix it. Don’t assume just an indication

I will try both tanks to help understand a possible vent issue. Looking through historical data this looks unlikely looking at the duration of the issue and how I usually manage fuel.

Fuel filter was cleaned out at the last CI and I see this issue in the data both before and after the CI so I don't think that is likely. I will go inspect for leaks there again though.

Thank you. I'll check the markings.Just to clarify, you can't necessarily judge visually whether you have an old Kavlico sensor based on appearance alone. I agree that updated sensors which look like the bottom image are available, but one of the approved replacements is the Kavlico P4055-5020 series, which is visually the same as the top image. You have to look at the markings to be sure.

Bill.Peyton

Well Known Member

It appears your sending units have Teflon tape on the threads. How many more places was Teflon tape used? RTV and Teflon tape on any fuel fittings is a big no no. There are better products. I use loctite 567 thread sealant.

You’re 100% correct. Good catch. I have not seen it on any other fittings but I’ll give it a closer inspection.It appears your sending units have Teflon tape on the threads. How many more places was Teflon tape used? RTV and Teflon tape on any fuel fittings is a big no no. There are better products. I use loctite 567 thread sealant.