An alternate thought - try to picture an unfamiliar pilot if you ever plan to sell or share your plane

As a boy I was in the back of a plane that had a pilot that was new to the type and the trim CB popped (due to tightness in the linkage). It was located next to the yoke but obscured for this pilot. It was never located before the "landing"

The resulting nose heavy trimmed landing resulted in a porpoise, folded gear and two rebuilt engines. Lots of other things went wrong obviously, but the first link in the chain was that the pilot was not able to locate the disconnect under pressure.

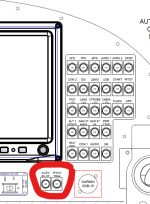

Whatever you do, keep it simple. Acknowledging the problem of searching for a specific breaker in a sea of buttons is great. Most of our system failures are non events and adding distractions (like too many breakers) can exacerbate the problem. Could you find a critical switch/cb in the dark, by feel?

My choice was (1) Alt Field cb and (2) A/P disconnect switch for trim and servos... and the A/P switch is probably non required.

The Alt Field is near the Battery switches and the A/P cb is near the A/P panel, keeping them grouped by function.

+1 on keeping it simple - as complicated as it needs to be but no more than that.

I focussed on the flow - most important from left to right.

Loss of trim is more likely based on component failure rates than trim runaway so the system is designed to minimize loss of function. I can live with full out of trim stick loads in worst case situation so no additional switches

KeithTurner