I have an IO-360B2B with a Bendix RSA-5AD1 servo with a SDS SDI ignition on the upper plugs and Slick traditional mag firing bottom plugs. I just completed my condition inspection (CI) in December where I had replaced the upper NGK BR8ES solid 3961 plugs, cleaned and re-gapped the lower plugs, and removed and cleaned all the full injectors in Hoppes. In the flights since my CI, Cylinder #3's EGT has increased about 80-100 degrees from where it has been for the last 1000 hrs. No other symptoms as engine runs smooth just like it always has. The higher EGTs in Cyl #3 started first flight after CI only showing hotter when I leaned. I have tried swapping the #1 & #3 EGT probes, re-cleaning the #3 injector, and swapping the #1 and #3 injector with no change. Actually #3 is now hotter than the rest of the cylinders by 50-60 degrees at any time above 50% power, no matter the mixture. I am in the process of swapping the #1 and #3 EGT lead to my JPI EDM-700 to see if it is a wiring issue or something else instrumentation related. Next things to try are removing and checking the plugs, doing a borescope on Cylinder #3 (although all looked good a few hours ago at the CI), and inflight mag checks. Any other thoughts on what to try?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cause for one cylinder to suddenly increase EGT over several flights

- Thread starter plehrke

- Start date

That dosent seem to be a large spread. 3 things come to mind when I see this on my 0360, 1 plug misfiring, induction leak, or a leaner cylinder.

Not a large spread but a sudden change of being my coolest EGT by 50 degrees to be my hottest EGT by 50 degrees happening in 3 hours following my condition inspection.That dosent seem to be a large spread. 3 things come to mind when I see this on my 0360, 1 plug misfiring, induction leak, or a leaner cylinder.

You may also want to check the fuel flow to each of the cylinder to see if that shows a big discrepancy. You could have something restricting number 3 in the spider. It does not take much to restrict the flow. Disconnect the fuel lines at the nozzles and do a flow check to see if all four cylinders get close to the same fuel amount.Not a large spread but a sudden change of being my coolest EGT by 50 degrees to be my hottest EGT by 50 degrees happening in 3 hours following my condition inspection.

Check the manifold pressure sensor, I’ve had a couple fail.I have an IO-360B2B with a Bendix RSA-5AD1 servo with a SDS SDI ignition on the upper plugs and Slick traditional mag firing bottom plugs. I just completed my condition inspection (CI) in December where I had replaced the upper NGK BR8ES solid 3961 plugs, cleaned and re-gapped the lower plugs, and removed and cleaned all the full injectors in Hoppes. In the flights since my CI, Cylinder #3's EGT has increased about 80-100 degrees from where it has been for the last 1000 hrs. No other symptoms as engine runs smooth just like it always has. The higher EGTs in Cyl #3 started first flight after CI only showing hotter when I leaned. I have tried swapping the #1 & #3 EGT probes, re-cleaning the #3 injector, and swapping the #1 and #3 injector with no change. Actually #3 is now hotter than the rest of the cylinders by 50-60 degrees at any time above 50% power, no matter the mixture. I am in the process of swapping the #1 and #3 EGT lead to my JPI EDM-700 to see if it is a wiring issue or something else instrumentation related. Next things to try are removing and checking the plugs, doing a borescope on Cylinder #3 (although all looked good a few hours ago at the CI), and inflight mag checks. Any other thoughts on what to try?

Do you know what your manifold/RPM timing curve is?

Carl Froehlich

Well Known Member

Result of your mag check?

Carl

Carl

D-Dubya

Well Known Member

Cause and effect would point to something done during the annual CI. Did you open up the servo and/or clean the fuel strainer? Were any of the hoses removed or replaced downstream of the servo? Is there any chance a piece of crud got knocked loose and worked its way into the fuel distribution "spider". You could do a flow test into test jars to see what the flow is looking like coming from the spider. With all of that said, a 50 or 100 degree spread of EGTs really isn't a big deal. CHTs, yes...but EGTs aren't necessarily a show-stopper in this case.

My guess is the #3 injector had a very small piece of junk in it that got cleared out with the hoppes treatement and this made a small enrichment. 50* hotter doesn't help. Need to know if it was peak, ROP or LOP when observing this temp, as higher EGTs mean different things on either side of peak. Generally, higher EGTs across the board means richer and more power, but that is not universal.I have an IO-360B2B with a Bendix RSA-5AD1 servo with a SDS SDI ignition on the upper plugs and Slick traditional mag firing bottom plugs. I just completed my condition inspection (CI) in December where I had replaced the upper NGK BR8ES solid 3961 plugs, cleaned and re-gapped the lower plugs, and removed and cleaned all the full injectors in Hoppes. In the flights since my CI, Cylinder #3's EGT has increased about 80-100 degrees from where it has been for the last 1000 hrs. No other symptoms as engine runs smooth just like it always has. The higher EGTs in Cyl #3 started first flight after CI only showing hotter when I leaned. I have tried swapping the #1 & #3 EGT probes, re-cleaning the #3 injector, and swapping the #1 and #3 injector with no change. Actually #3 is now hotter than the rest of the cylinders by 50-60 degrees at any time above 50% power, no matter the mixture. I am in the process of swapping the #1 and #3 EGT lead to my JPI EDM-700 to see if it is a wiring issue or something else instrumentation related. Next things to try are removing and checking the plugs, doing a borescope on Cylinder #3 (although all looked good a few hours ago at the CI), and inflight mag checks. Any other thoughts on what to try?

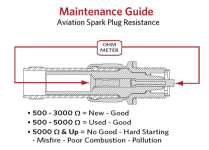

Larry

Could be the #3 injector but when you did the C.I. did you check the resistance of the plugs? Since you put new plugs on top I suspect these are OK. The bottom plugs sound like aviation plugs since you have a mag running those. Resistance should be in the 500-3000 ohm range for a good plug. Not an A&P but found the image below a while ago but not sure of the source. It may have been one of the numerous Savvy Aviation maintenance articles. Just a thought……I have an IO-360B2B with a Bendix RSA-5AD1 servo with a SDS SDI ignition on the upper plugs and Slick traditional mag firing bottom plugs. I just completed my condition inspection (CI) in December where I had replaced the upper NGK BR8ES solid 3961 plugs, cleaned and re-gapped the lower plugs, and removed and cleaned all the full injectors in Hoppes. In the flights since my CI, Cylinder #3's EGT has increased about 80-100 degrees from where it has been for the last 1000 hrs. No other symptoms as engine runs smooth just like it always has. The higher EGTs in Cyl #3 started first flight after CI only showing hotter when I leaned. I have tried swapping the #1 & #3 EGT probes, re-cleaning the #3 injector, and swapping the #1 and #3 injector with no change. Actually #3 is now hotter than the rest of the cylinders by 50-60 degrees at any time above 50% power, no matter the mixture. I am in the process of swapping the #1 and #3 EGT lead to my JPI EDM-700 to see if it is a wiring issue or something else instrumentation related. Next things to try are removing and checking the plugs, doing a borescope on Cylinder #3 (although all looked good a few hours ago at the CI), and inflight mag checks. Any other thoughts on what to try?

Darren Kerns

Well Known Member

PhilipI have an IO-360B2B with a Bendix RSA-5AD1 servo with a SDS SDI ignition on the upper plugs and Slick traditional mag firing bottom plugs. I just completed my condition inspection (CI) in December where I had replaced the upper NGK BR8ES solid 3961 plugs, cleaned and re-gapped the lower plugs, and removed and cleaned all the full injectors in Hoppes. In the flights since my CI, Cylinder #3's EGT has increased about 80-100 degrees from where it has been for the last 1000 hrs. No other symptoms as engine runs smooth just like it always has. The higher EGTs in Cyl #3 started first flight after CI only showing hotter when I leaned. I have tried swapping the #1 & #3 EGT probes, re-cleaning the #3 injector, and swapping the #1 and #3 injector with no change. Actually #3 is now hotter than the rest of the cylinders by 50-60 degrees at any time above 50% power, no matter the mixture. I am in the process of swapping the #1 and #3 EGT lead to my JPI EDM-700 to see if it is a wiring issue or something else instrumentation related. Next things to try are removing and checking the plugs, doing a borescope on Cylinder #3 (although all looked good a few hours ago at the CI), and inflight mag checks. Any other thoughts on what to try?

I experienced that same thing on my RV7 #3 cylinder after condition inspection last spring. I am running about 20 degrees hotter on my EGT. Around 1412-1416. All others right at 1400 EGT. CHT's are great. I also use Tempest Fine Wire plugs too.

I had my Slick mags redone, Prop & governor redone. All new TS integral fire-sleeved hoses as well. Oil return lines too. Tom is outstanding. Best money I ever spent. My mechanic said my #3 injector was almost completely clogged up. I am glad we found it.

I have talked to them how it runs hotter and all have said I am fine. CHT's are what you want to watch.

Therefore, I just keep flying and run her good. Good luck & I think you have nothing to worry about.

Darren Kerns

RV7 N599DT

KFRH

Last edited:

Toobuilder

Well Known Member

Is this EGT observation at full throttle? If so, an intake leak will not manifest in high EGT. Suggest a “bottle test” on the injectors. Likely some small restriction. My track record with injector maintenance runs about 50% success - no matter how clean I think I am, I often end up dislodging some junk that ends up in the nozzle within a few minutes of the post maintenance flying.

Darren Kerns

Well Known Member

I am running around 24.2/2420. i checked the #3 injector the other day & I thought I found a small speck in it. I cleaned it out and then test flew the next day. Still showing a little higher on the #3 EGT. When I back off the power entering to land, she drops back pretty quickly.Is this EGT observation at full throttle? If so, an intake leak will not manifest in high EGT. Suggest a “bottle test” on the injectors. Likely some small restriction.

They borescoped my cylinders back at the CI and they all looked good. When it warms up more, I think I am going to pull the plugs and check them again and borescope it with my borescope. Could check the injector again. I just pulled the little inlet sleeve out and examined it. I don't think that is the right name for it.

I don't know what else to look at. I sometimes wonder if my mag timing should be checked again. My #3 & #4 EGT always run just a little hotter than the others after the CI.

Thanks for help. Any advice sure is appreciated.

Darren

And the issue was . . . . . Bad lower spark plug (one fired from magneto).

I should have followed a few of your’s advice and done the easy inflight mag check earlier in the diagnostic process. Mag check at 1800 rpm had not shown any issues. At altitude, leaned to peak, the EGT dropped like a rock when I switched off the SDS CPi. It was obvious the plug was not firing. What was amazing was how smooth the engine ran with only the electric ignition plug firing. The only indication I had that anything was amiss was never rough running engine but that the EGT in that cylinder had changed to be about 80 degrees hotter then its long 1000 hour history. That was only noticed because it become my hottest EGT after 15 years of not.

As I had mentioned I was just out of my condition inspection when this started to occur. I had changed out the 15 year old non-Teflon hose from the fuel injection servo to the spider so I was fixated on the spider being contaminated. Not to be. Lesson learned, look at the entire playing field.

When I saw the EGT drop in the in-flight mag check I instantly remembered that I had “sort of” dropped a plug cleaning it in the bead blast cabinet at condition inspection. You have those rubber gloves that you stick your hands/arms in to grab a plug and operate the nozzle. I dropped one plug from about 6-8” high inside the bead blast onto the lower screen. I thought about the rule if you drop a plug once you should drop it again into the trash. I dismissed it because it was not very high a drop and onto a very porous, flexible grate. Lesson learned, dropping a plug from any height means it should be replaced.

Now you know the reeeest of the story!

I should have followed a few of your’s advice and done the easy inflight mag check earlier in the diagnostic process. Mag check at 1800 rpm had not shown any issues. At altitude, leaned to peak, the EGT dropped like a rock when I switched off the SDS CPi. It was obvious the plug was not firing. What was amazing was how smooth the engine ran with only the electric ignition plug firing. The only indication I had that anything was amiss was never rough running engine but that the EGT in that cylinder had changed to be about 80 degrees hotter then its long 1000 hour history. That was only noticed because it become my hottest EGT after 15 years of not.

As I had mentioned I was just out of my condition inspection when this started to occur. I had changed out the 15 year old non-Teflon hose from the fuel injection servo to the spider so I was fixated on the spider being contaminated. Not to be. Lesson learned, look at the entire playing field.

When I saw the EGT drop in the in-flight mag check I instantly remembered that I had “sort of” dropped a plug cleaning it in the bead blast cabinet at condition inspection. You have those rubber gloves that you stick your hands/arms in to grab a plug and operate the nozzle. I dropped one plug from about 6-8” high inside the bead blast onto the lower screen. I thought about the rule if you drop a plug once you should drop it again into the trash. I dismissed it because it was not very high a drop and onto a very porous, flexible grate. Lesson learned, dropping a plug from any height means it should be replaced.

Now you know the reeeest of the story!