Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Borescope advice

- Thread starter rvanstory

- Start date

Bill.Peyton

Well Known Member

It really does not look that bad to me. How was the compression? It’s so easy to accomplish the lapping in place and if you are on the fence, you should go ahead a do it. I have done every one of my exhaust valves in the 1500 hours of operating time on my engine. In all cases the issue was resolved Some of mine looked quite a bit worse than yours.

Exhaust lapping

Agree this doesn't look bad, but also: What compressions are you seeing? White lead deposits accumulating over time on the valve seat are usual, and the reasonably straight forward lapping process will get rid of the deposits and can recover some lost compression. On the other hand, for most moderate deposits and mild compression deficits, lapping is not absolutely necessary, as under operating pressures, the leakage is not significant. However, if you see exhaust valve hot spots (not apparent in your picture), then it's time to check for lack of valve rotation, and fix that first, then possibly lapping. There are some real good presentations of lapping as well as diagnosing lack of valve rotation issues on Mike Busch's site

https://resources.savvyaviation.com/resources/mikes-articles/

Agree this doesn't look bad, but also: What compressions are you seeing? White lead deposits accumulating over time on the valve seat are usual, and the reasonably straight forward lapping process will get rid of the deposits and can recover some lost compression. On the other hand, for most moderate deposits and mild compression deficits, lapping is not absolutely necessary, as under operating pressures, the leakage is not significant. However, if you see exhaust valve hot spots (not apparent in your picture), then it's time to check for lack of valve rotation, and fix that first, then possibly lapping. There are some real good presentations of lapping as well as diagnosing lack of valve rotation issues on Mike Busch's site

https://resources.savvyaviation.com/resources/mikes-articles/

rvanstory

Well Known Member

How was the compression?

Thanks for responding! Compression was good (71/80 cold). I’ve helped a friend do this. It was pretty simple. So, I may go ahead just to get ahead of it since I’m on the fence.

Bill.Peyton

Well Known Member

71 is a bit low for the time on your engine, even if it was cold. I had one that low and brought it back up to 79 after lapping the exhaust valve.

pa38112

Well Known Member

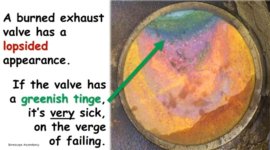

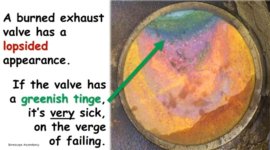

It has started to fail. "It does not look bad" just means it is not on the verge of failing. Lapping it may bring the temps back down, but it has seen over-temp already. The metal has ben stressed. Spend the money for a subscription to Savy Analysis and send them the phots plus your engine monitor data. I would trust them compleately to advise how much this should worry you. It will be $129 well spent.

I would also perform a wobble test on that valve...

I would also perform a wobble test on that valve...

didn't see this originally. It looks to me that approximately 1/4 of the circumference of the valve seating area is not making contact with the seat. Several reasons for this. Lapping is a good first attempt to addess it, but it could also be an issue with the way the seat was ground. No gaurantee that lapping will address it, as that is taking off a microscopic layer of metal and really only works if the issue is debris or VERY small imperfections. Is this the first borescope? Would be helpfull to know if this just showed up or has been around since the beginning. my first guess is that the seat was ground with the tooling slightly off parallel from the guide (not tightening the pilot stem enough).

Insert the scope through the other plug hole and try to get a look at the seat contact surface. You should notice a distinct difference in the look of the contact area where the valve is not making contact vs where it is. If you see a chunk of debris at the center causing the gap, then lapping should clean it up.

Larry

Insert the scope through the other plug hole and try to get a look at the seat contact surface. You should notice a distinct difference in the look of the contact area where the valve is not making contact vs where it is. If you see a chunk of debris at the center causing the gap, then lapping should clean it up.

Larry

Last edited:

jcbarker

Well Known Member

Borescope vs compression with Mike Bush

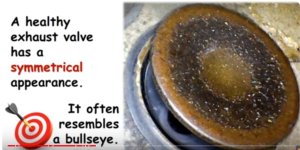

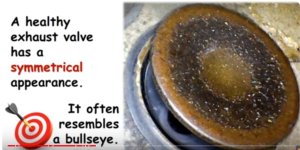

This is very timely. I just watched this presentation by Mike Bush. I, like most of us that work on our own airplanes, believed that compression was the final decider. Watch this video and learn why the FAA has done away with that requirement. Instead borescopy is now the method to determine valve health. There's a chart that shows what good valves look like and valves that are about to fail. l think your valve looks pretty sick. But watch the video and you decide.

This is very timely. I just watched this presentation by Mike Bush. I, like most of us that work on our own airplanes, believed that compression was the final decider. Watch this video and learn why the FAA has done away with that requirement. Instead borescopy is now the method to determine valve health. There's a chart that shows what good valves look like and valves that are about to fail. l think your valve looks pretty sick. But watch the video and you decide.

jcbarker

Well Known Member

jcbarker

Well Known Member

chart showing valve health

here's a link to download a pdf of the chart:

https://www.aopa.org/-/media/Files/...ety/14FN0000-ASI-Valve-Safey-Poster_Final.pdf

here's a link to download a pdf of the chart:

https://www.aopa.org/-/media/Files/...ety/14FN0000-ASI-Valve-Safey-Poster_Final.pdf

Dr_Dave_MT

Well Known Member

Boroscopy

Great video. The irregularity of that valve’s surface coloring concerns me. But to be able to send images to Savvy would be worth the cost of their analysis. I also see a new toy, I mean “tool” to add to my arsenal in the shop.

This is very timely. I just watched this presentation by Mike Bush. I, like most of us that work on our own airplanes, believed that compression was the final decider. Watch this video and learn why the FAA has done away with that requirement. Instead borescopy is now the method to determine valve health. There's a chart that shows what good valves look like and valves that are about to fail. l think your valve looks pretty sick. But watch the video and you decide.

View attachment 50910

View attachment 50911

Great video. The irregularity of that valve’s surface coloring concerns me. But to be able to send images to Savvy would be worth the cost of their analysis. I also see a new toy, I mean “tool” to add to my arsenal in the shop.

Jetmart

Well Known Member

This is another very good video. Perhaps better than Mike Bush's.

Well worth the watch.

https://youtu.be/Dk5o4__0y-4?feature=shared

Well worth the watch.

https://youtu.be/Dk5o4__0y-4?feature=shared

rvanstory

Well Known Member

This is another very good video. Perhaps better than Mike Bush's.

Well worth the watch.

https://youtu.be/Dk5o4__0y-4?feature=shared

This is an excellent video that I have not seen. Thank you for sharing.