The stance of Van’s Aircraft remains the same. If flown properly the older Wittman-style nose gear will be fine. The reality is that pilots do not receive proper training. Mike Segar and I presented an EAA webinar called Critical RV Flying Skills that all RV pilots should be aware of.

https://www.eaa.org/videos/6155295734001. In short RV Pilots especially those that have bought a used aircraft do not practice slow flight, they land too fast, they balloon on landing, they bounce in a landing, and do not go around. Rember this one thing, if the landing is not going well, go around. After the first bounce, the airspeed decreases to the point that the pilot is unable to maintain a nose-up pitch attitude. The aircraft comes down on the nose gear at an angle that will create a significant drag load. This causes the gear to fail in an aft direction.

Since the failure is related to drag any contributor to the drag force will reduce the failure margin. Here are areas that may increase the margin.

Anti-Splat

The Anti-Splat system stiffener may give slightly more margin to this failure mode but in many cases, it will not prevent the failure. We have documented cases of nose gear failures with the Anti-Splat system installed that still resulted in a flip-over accident. What is unknown about the Anti-Splat system is the long-term affects on the gear fatigue life. The gear was re-designed in the late 90’s and early 2000's because the first-generation gear was failing in fatigue where the gear entered the socket. Anti-Splat stiffens the gear which moves the point at which the gear will flex upwards towards the socket. This may affect the fatigue life of the gear. So far, we have not seen any fatigue failures with Anti-Splat installed. Overall know that Anti-Splat will not cover up poor pilot skills. If you are uncomfortable landing, then get training and practice as mentioned in the webinar above. If you really want more margin, install the new gear design.

Nose Wheel Clear of Ground

Keep the nose wheel off the ground after touchdown until just above the speed at which you can gently lower the nose gear (too slow and the nose will fall as the tail becomes ineffective at low speeds).

Just as important pilots should lift the nose wheel as soon as possible as they start the takeoff roll. This helps the nose wheel from a loads standpoint but even more important our aircraft is a free castering nose wheel. It is amazing the number of pilots who hold the nose gear on the runway as they were taught in training with a Cessna.

For aircraft with a steerable nose wheel keeping the nose wheel on the ground is normal and stable. Free castering wheels are unstable as they remain on the ground and go faster. As soon as the nose wheel lifts the rudder becomes much more effective because the nose wheel is no longer inhibiting the rudder from moving the nose. There is more directional control lifting the nose wheel as soon as possible. Also at this point, you are not looking for a speed to rotate, instead, you are looking outside the aircraft down the runway and waiting for the aircraft to lift itself off the runway. Since RV’s have a power-to-weight ratio greater than most certified aircraft there is no issue with lifting off this way and then needing to push the nose of the aircraft down. You may keep the same attitude and continue to climb. This takeoff method is similar to a soft field takeoff. Takeoff distances will be significantly shorter holding the wheel just off the ground than holding the wheel on the ground until a rotation speed is achieved (if you believe this is not true it is because you may be holding the nose wheel too high off the ground).

Lifting the nosewheel clear of the ground should be used for every takeoff regardless of the runway surface type.

Tire Pressures

Use the correct nose wheel tire pressure. Too low of pressure and the friction is too high creating a large drag force. Too high of a pressure and the tire is more likely to shimmy.

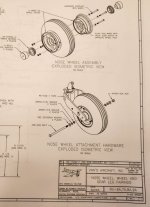

Nose Wheel Axel

Older installations used spacers on either side of the nose wheel. These would in some cases rotate with the wheel. To prevent this, builders would tighten the nose wheel axle bolt creating extra rotational friction of the wheel as the spacers add side pressure to the nose wheel bearings which are not meant to be loaded in this direction. To eliminate this as a problem we have introduced a new nose wheel axle. This axle was designed after a review of other axel replacement solutions on the market. All builders (even if they will not be replacing the nose gear) should upgrade to the U-00710 and U-00711 axle system.

RV-8A

Van’s Aircraft has not retrofitted the new nose gear system on the RV-8A for two reasons. First, the number of these models is very low. Due to the low number of 8A’s flying or the type of pilots that are attracted to this aircraft, we have not seen failures on this model. Again, we feel the old nose gear design is adequate if flown properly. Our RV-7A demonstrator still uses the old-style gear and is regularly used for transition training. Some of us who work here who own RV A models also use the older style gear. Pilot training is key.

New Nose Gear System

Scott McDaniel’s post already reflects the viewpoint of the company, “The new nose gear wasn’t developed because the original was bad. It was because it could be made better… to a point that provides more safety margin for the broad range of experience in the pilots that choose to fly them.”

One builder has noted the RV-14A flip-over accident in Australia. See Ashley Miller's post in response to this. The flip-over accent in this instance was driven by a number of factors noted by Ashley in which any aircraft may flip over. It is important to note that there has been an RV-14 landing documented in a field and in another instance, the nose gear struck a large rock on an unimproved strip. The nose gear as intended in these instances failed at the top of the post which holds the isolators then folded under the aircraft. These aircraft did not flip over. There is far less chance of the aircraft flipping over with the new gear style. Therefore, if a pilot truly wanted more margin, they would retrofit the new gear style. We designed the RV-14A for FAR23 loads for the training environment to be sold after the implementation of MOSAIC. To meet the ASTM F37 F2245 requirements the design is inherently stronger than the previous design which reflected the era in which it was designed.

ATSB Video

The opinion of ATSB to recommend upgrading to the new style nose gear is their own. The new nose gear will give more margin. Also, awareness about proficiency issues that cause poor landings will result in pilots thinking about how they fly even if using the old nose gear. Pilots also should use the new axle and correct tire pressures. The ATSB video raises this awareness. For this reason, I did review and give guidance to the ATSB in making their video. Van’s Aircraft actively works with transportation safety boards worldwide. We all want to see aviation become safer, which ultimately keeps the price of aircraft lower and prevents insurance rates from escalating. From that standpoint, we are all in this together.

Rian Johnson, President Van's