Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

100f oil temp?

- Thread starter larryMar

- Start date

See -- https://www.lycoming.com/sites/defa...0%26%20TIO-360%20Oper%20Manual%2060297-12.pdf

Page 3-11, note at the bottom -- included for convenience:

* - Engine oil temperature should not be below 140°F (60°C) during continuous operation.

Page 3-11, note at the bottom -- included for convenience:

* - Engine oil temperature should not be below 140°F (60°C) during continuous operation.

dmattmul

Well Known Member

Personal

I think the only thing you will find from Lycoming is the engine should not hesitate during throttle advancement or something like that. I like to see 110 F before I do a run-up but again just personal. If less than that I get a hesitation. In flight like to see 165 to 195 F.

I think the only thing you will find from Lycoming is the engine should not hesitate during throttle advancement or something like that. I like to see 110 F before I do a run-up but again just personal. If less than that I get a hesitation. In flight like to see 165 to 195 F.

Last edited:

Majorpayne317641

Well Known Member

It really depends on what weight oil you are using, if you use multi weight engine oil it is designed to work across a broad range of temps as listed for the oil you are using. I like to wait to 100 degrees but that’s for any engine, aircraft, tow truck, or race car before I do full throttle. Just a habit but also good technique to allow things to warm up and so oil has a chance to get where it needs before you stress the engine.

I suspect it's more of the oil temp indicator coming off the peg on mechanical gauges. With ambient temps in the 90s it's wise to know that the oil temp gauge is actually working.

Exactly. My GRT EFIS sits at 59F when it's "on the peg". I don't taxi until I see something higher than 59F. Then I take Lycoming's advice and do the run up when you can throttle up with no hesitation. With a multi-weight oil this is a very low temperature. Even a quick run up on a cold day typically gives time for the oil to get to over 100F before takeoff. Obviously if the OAT is already 80F or higher this is not an issue at all.

Yes Robin, I agree. I have always used 200f cylinder temps prior to runup.

I us 20w50, heat in the winter. (engine compartment is about 75f) My OT is analog, and I never see it move until shortly after T/0. I always thought Lycoming advises not to prolong the ground time - get it flying.

Thanks

I us 20w50, heat in the winter. (engine compartment is about 75f) My OT is analog, and I never see it move until shortly after T/0. I always thought Lycoming advises not to prolong the ground time - get it flying.

Thanks

YI always thought Lycoming advises not to prolong the ground time - get it flying.

Thanks

That is the general wisdom. However, this 100* OT thing just will not go away and folks seem to give that MUCH higher priority. I see guys idling on the ramp for 15-20 minutes in the winter trying to reach that magic number. All my engine experience and knowledge tells me that Lyc is correct - get the key parameters (like cyl temp) to where they need to be and then go.

Auburntsts

Well Known Member

I think folks are getting the 100* thing from their previous aircraft experience and are carrying it forward not having really read the Lycoming Operators Manual that doesn't specify a minimum warm up temp. For example, the oil temp gauge markings in late model Cessnas show the green arc "normal" operating temp range as 100* to 245*. So methinks that folks are thinking they have to get it to 100* before takeoff because the gauge is tells them to and that's what they were taught.

gauge markings

I think this is somewhat relevant to this conversation. My Mitchell oil temp gauge has what I would call a nonlinear scale. It has a couple unlabeled tick marks on it that due to the non-linearity I cannot assume what temps they are trying to indicate. I have searched for a manual but can't find anything that matches this gauge. Anybody know for sure what these marks indicate?

As far as waiting till 100 degrees to fly, I do usually wait until I see the needle move off its rest, which for me is right around 100 degrees as you can see in the pic.

I think this is somewhat relevant to this conversation. My Mitchell oil temp gauge has what I would call a nonlinear scale. It has a couple unlabeled tick marks on it that due to the non-linearity I cannot assume what temps they are trying to indicate. I have searched for a manual but can't find anything that matches this gauge. Anybody know for sure what these marks indicate?

As far as waiting till 100 degrees to fly, I do usually wait until I see the needle move off its rest, which for me is right around 100 degrees as you can see in the pic.

Attachments

That is the general wisdom. However, this 100* OT thing just will not go away and folks seem to give that MUCH higher priority. I see guys idling on the ramp for 15-20 minutes in the winter trying to reach that magic number. All my engine experience and knowledge tells me that Lyc is correct - get the key parameters (like cyl temp) to where they need to be and then go.

But -- with the caveat that a too low Oil Temperature *will* cause a too high Oil Pressure when you get the RPM up to take off speed.

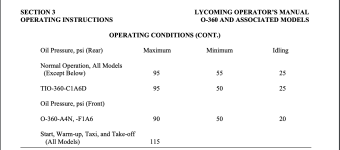

Again, referencing the IO-360 Operating Handbook (link https://www.lycoming.com/sites/defa...0%26%20TIO-360%20Oper%20Manual%2060297-12.pdf) page 3-12. Maximum Oil Pressure 115 PSI. (screen grab attached)

Attachments

FWIW

I’m not sure where the 100 degrees thing started. However, when I took delivery of my factory new 0-360 from Lycoming last year, the gentleman at Lyc I was working with recommended 100 for takeoff. I recall him saying that they used to recommend 80, but now like to see 100.

That’s what I do now, assuming all other parameters are ok.

I would imagine that there’s some common sense wiggle room here.

I’m not sure where the 100 degrees thing started. However, when I took delivery of my factory new 0-360 from Lycoming last year, the gentleman at Lyc I was working with recommended 100 for takeoff. I recall him saying that they used to recommend 80, but now like to see 100.

That’s what I do now, assuming all other parameters are ok.

I would imagine that there’s some common sense wiggle room here.

Majorpayne317641

Well Known Member

I’m not sure where the 100 degrees thing started. However, when I took delivery of my factory new 0-360 from Lycoming last year, the gentleman at Lyc I was working with recommended 100 for takeoff. I recall him saying that they used to recommend 80, but now like to see 100.

That’s what I do now, assuming all other parameters are ok.

I would imagine that there’s some common sense wiggle room here.

Pretty much all ICE engines like that as a sweet spot for full throttle.