Can you of you guys share a pic or to of the pin installed in your stinger?

I replaced a bent spring non-castering tailwheel with the Fly Boy Accessories spring and lightweight tailwheel on our 6 earlier this year - Not because there was a problem with the spring or socket being loose, but because the end of the bent spring would catch on the edge of the hard stand and other divots in the taxiways, and I was worried I’d damage the tail structure of the plane. I had maybe 3/4” of clearance between the ground and end of the spring.

This is what I ended up replacing:

The old spring was held in the fuselage weldment with a standard AN4 bolt put in from the top. (I had to remove the Elevator to get sufficient access to the bolt. It was just as well I did as I also found the left elevator spar cracked from the outboard rod-end rivet.)

(I had to ease out the whole in the skin a little to get a thin wall socket over the nut as the skin hole and weldment hole weren’t concentric)

Old tailwheel and new

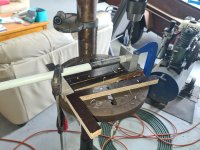

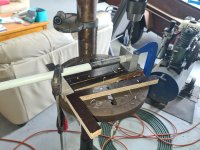

Match drilling the new spring to the hole in the old spring meant making a jig to clamp around the old spring, drill one half of the jig, then with a 1/4” diameter pin through the first half of the jig and old spring, I clamped the other half of the jig in place, removed the pin and drilled the second half of the jig through the first half and old t/w spring. Drilling back through the first half of the jig and old T/W spring:

I then clamped the Jig around the new T/W spring and drilled the new spring from each side of the spring to meet in the middle. I used a brand new carbide drill for the hole in the new spring.

The alignment of the holes in the weldment and new spring wasn’t quite perfect enough to drop the bolt back in

. I had planned to use a taper pin in any case and the slight misalignment was taken care of by the taper pin. Access in from the top was not going to happen with the ream so it went in from the bottom, (very Slowly!)

(a lot of breaks and cooling fans in the Australian summer)

I checked the aircraft was level in roll, and tyre pressures were even & then used the hangar floor to make sure the tailwheel yoke was square and then drilled holes for it in-situ.

Using the Brown and Sharpe close to hangar floor was quite awkward and on the second hole in the tailwheel yoke I snapped the taper off

. Thankfully being a tapered ream I could knock it back out the hole and it only cost me a week and a new B&S #1 tapered ream.

I painted the spring & tailwheel socket as a unit

Job done and definitely one of the better value upgrades for our RV-6. Ground handling and in particular directional control while taxiing is worlds apart from the old sloppy slack chains and springs.

I don’t have any specific photos of the taper pins in the fuselage, but I hope some of the above is helpful.

Don H

Sydney, Aus