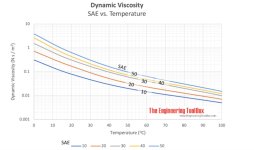

Quick question; I just had my 0-320 E2D 8.5 CR overhauled with an entire new top end from Superior. The engine builder put in 40WT AeroShell. During a flight this morning my oil pressure settled at 50PSI at cruise (75%) power. 81F OAT at 6500MSL Oil Temp 210. I wasn't happy with this so I cut the flight short to do some further investigation. My first inclination was to try 50WT AeroShell and see if this would result in higher pressure. I have looked around the internet for some type of graph or formula to see what changing viscosity might do to pressure readings to no avail. I spoke with the engine builder and he did not seem to concerned. He suggested I run the engine at full power on the ground at operating temp and see what the pressure reading is before I change to a heavier oil. The oil pressure was set during the test run at 79PSI per Lycoming instruction. I am running a brand new Mitchel electronic oil press gauge (Model number D1-211-5056 with the appropriate sending unit). I am going to test it for accuracy tomorrow.

I'm thinking since I have already seen the lower viscosity in action I might just pump out (Or pull the cowl and drain) the oil and start over with 50WT.

Anyone have practical experience with this or any real world results of changing oil weights vs Pressure?

Thanks!

I'm thinking since I have already seen the lower viscosity in action I might just pump out (Or pull the cowl and drain) the oil and start over with 50WT.

Anyone have practical experience with this or any real world results of changing oil weights vs Pressure?

Thanks!