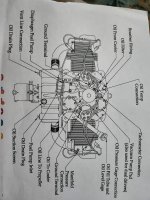

Yesterday I tried to install the VA-128 45 degree restrictor fitting into the oil port above the e-mag on my -EXP119 engine per KAI 43-05. About 1/2 turn before reaching the 45 degree clocking position, the fitting solidly bottomed out, as if the port was not threaded all of the way through the accessory case (but I don't know if it should be). Two A&P friends looked at this, and agreed with this observation. It's hard to see in the attached photo, but with a flashlight we were able to see the upper area of the threaded port appeared to be obstructed, again, as if not threaded completely through.

The FWF kit contains two VA-128 fittings so I tried both with the same result. So what's the solution? I could slightly file back the VA-128 at the restrictor end to allow proper tightening and clocking (filing back anything over 1/2 thread should be enough), but it's surprising I should have to. Or I could "assume" Lycoming made a mistake on the accessory case, and tap the port the rest of the way through (which might require removing the accessory case) but do not want to make a $$$$ mistake. Has anyone else run into this? Thanks!

The FWF kit contains two VA-128 fittings so I tried both with the same result. So what's the solution? I could slightly file back the VA-128 at the restrictor end to allow proper tightening and clocking (filing back anything over 1/2 thread should be enough), but it's surprising I should have to. Or I could "assume" Lycoming made a mistake on the accessory case, and tap the port the rest of the way through (which might require removing the accessory case) but do not want to make a $$$$ mistake. Has anyone else run into this? Thanks!