Desert Rat

Well Known Member

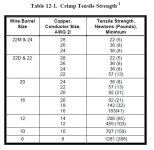

I was reading another thread where somebody was asking for troubleshooting help and one of the responses had an example picture that showed where a ring terminal had pulled off the wire. It was clearly a non-aviation terminal and by the indentations on the insulation, It looked like it was probably done with a cheap plier style crimper.

I could write a book about why you should only use PIDG terminals and a ratcheting crimper, but the simple answer is that you get what you pay for and with the non aviation stuff, there's a lack of consistency, both in the terminals and in the quality of crimp you get if you're not using ratcheting crimpers that have correctly sized dies.

So, with that being said, I thought it would be fun to set up a couple of test articles for a show and tell.

In the pictures below, the white wire is a 20 gauge with a red PIDG ring terminal. It will easily hold up to a 15 lb pull. I didn't take a subsequent picture, but it failed when I tried to hang it from a 25 lb weight.

The red wire is an 18 gauge, also with a red PIDG terminal. Because it's done with they same dies, the crimp is actually squeezing down harder on the bigger wire. It will support something more than 25 lbs. How much more I don't know because I didn't try to pull more weight than that.

In either case, if the pull is something other that linear, the ring terminal will bend before the crimp lets go.

Both of these were crimped with the middle of the road ratcheting crimper with the green handles that Stein sells.

I didn't have any cheap terminals or crimpers to compare and I'm not going buy any for just a fun little experiment like this. I suspect that I could get similar results for the pull test most of the time, but there would be an occasional failure due to lack of consistency in crimping.

What wouldn't be as apparent is how prone individual samples might be to problems on down the road due to the same "better safe than sorry" tendency that causes almost everybody to over torque bolts and spark plugs if they don't use a torque wrench. i.e. I don't want it to be too loose, so I'm gonna squeeze it a bit harder.

With the right tool and the right hardware, I get a crimp that absolutely WILL NOT pull out in its normal environment. At the same time it's not overdone and due to the design of the terminal there is strain relief built in. Both of these characteristics go a long way to minimize the chances having to chase down an intermittent fault 5 years from now after vibration or a less than optimal crimp has its way with some hardware store terminal deep in the guts of my airplane.

Just something to think about...

I could write a book about why you should only use PIDG terminals and a ratcheting crimper, but the simple answer is that you get what you pay for and with the non aviation stuff, there's a lack of consistency, both in the terminals and in the quality of crimp you get if you're not using ratcheting crimpers that have correctly sized dies.

So, with that being said, I thought it would be fun to set up a couple of test articles for a show and tell.

In the pictures below, the white wire is a 20 gauge with a red PIDG ring terminal. It will easily hold up to a 15 lb pull. I didn't take a subsequent picture, but it failed when I tried to hang it from a 25 lb weight.

The red wire is an 18 gauge, also with a red PIDG terminal. Because it's done with they same dies, the crimp is actually squeezing down harder on the bigger wire. It will support something more than 25 lbs. How much more I don't know because I didn't try to pull more weight than that.

In either case, if the pull is something other that linear, the ring terminal will bend before the crimp lets go.

Both of these were crimped with the middle of the road ratcheting crimper with the green handles that Stein sells.

I didn't have any cheap terminals or crimpers to compare and I'm not going buy any for just a fun little experiment like this. I suspect that I could get similar results for the pull test most of the time, but there would be an occasional failure due to lack of consistency in crimping.

What wouldn't be as apparent is how prone individual samples might be to problems on down the road due to the same "better safe than sorry" tendency that causes almost everybody to over torque bolts and spark plugs if they don't use a torque wrench. i.e. I don't want it to be too loose, so I'm gonna squeeze it a bit harder.

With the right tool and the right hardware, I get a crimp that absolutely WILL NOT pull out in its normal environment. At the same time it's not overdone and due to the design of the terminal there is strain relief built in. Both of these characteristics go a long way to minimize the chances having to chase down an intermittent fault 5 years from now after vibration or a less than optimal crimp has its way with some hardware store terminal deep in the guts of my airplane.

Just something to think about...