Charlie Sisk

Member

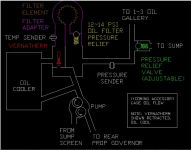

As to not high jack the other oil threads, I'll start this one. When comparing oil filters, burst strength always comes up. Champion and Tempest are 600 psi or so. The lowly Wix 51452 is only 420 psi. But...aint there always a "but".... what about the oil cooler ? Here are two references to oil cooler psi burst ratings.

www.aircraftspruce.com

Seems 400 psi is the number. So why are we so concerned about the oil filter pressure rating, and not about the oil cooler ? I always preheat below 50*F, I dont like to wait.

www.aircraftspruce.com

Seems 400 psi is the number. So why are we so concerned about the oil filter pressure rating, and not about the oil cooler ? I always preheat below 50*F, I dont like to wait.

If either oil filter or oil cooler turn loose, its gonna be a bad day. But a filter would be much faster to change.

Thoughts ?

Charlie

Aero-Classics Continental Oil Coolers | Aircraft Spruce

Aero-Classics Continental Oil Coolers Aero-Classics engine mounted oil coolers for Continental powered aircraft offer high quality features such as a CNC machined base for reliable, leak-proof mounting.

Airframe and Powerplant

Stabilizing your aircraft's oil system Rip Van Winkle didn't awake from his 20-year nap by jumping up and dancing a jig. He got up slowly and eased into warming up those old joints.

www.aopa.org

If either oil filter or oil cooler turn loose, its gonna be a bad day. But a filter would be much faster to change.

Thoughts ?

Charlie