I have always avoided using anything magnetic to hold my aviation purpose tools. My thinking has been the tools become magnetized and then in turn will magnetize the hardware in the airplane.

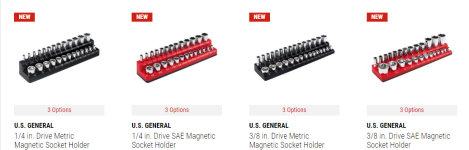

Am I overthinking this for all these years? Does anyone have experience with pros or cons of using magnetic tool holders in the hangar tool box?

Am I overthinking this for all these years? Does anyone have experience with pros or cons of using magnetic tool holders in the hangar tool box?