Draker

Well Known Member

Now that it's cold where I am (well at least California-Cold, which is not really cold as our midwestern friends will remind me) I'm seeing pretty low oil temps. It'll bottom out around 155F in cruise, in ~8C,45F OAT, but I have once seen an oil temp as low as 145F (similar OAT). This is consistent with what I observed during my initial flight tests last year, so nothing has recently changed.

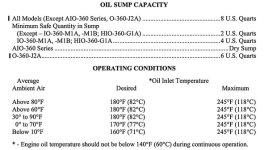

Lycoming's operating manual for my engine recommends several desired oil temperatures from 160F to 180F depending on ambient air temperature, and includes a note that oil should not be below 140F during continuous operation. And my understanding is that our oil systems include a vernatherm that opens and closes in order to regulate oil temperature by forcing it through the cooler when it gets hot (and presumably also blocks it from the cooler when it gets cool). Does the vernatherm require adjustment as the weather changes?

There are a couple of threads describing adding a pilot-controlled shutter onto the oil cooler, to block off the airflow when the oil is not warm enough. Looks like a few of the usual vendors including Vans sell these shutters. But what purpose do these shutters serve with the vernatherm controlling oil flow? Shouldn't the oil flow through the cooler be at a minimum if the oil itself is cool?

I suppose my oil temperature probe may be inaccurate too. Any good tips on how to measure its accuracy?

Lycoming's operating manual for my engine recommends several desired oil temperatures from 160F to 180F depending on ambient air temperature, and includes a note that oil should not be below 140F during continuous operation. And my understanding is that our oil systems include a vernatherm that opens and closes in order to regulate oil temperature by forcing it through the cooler when it gets hot (and presumably also blocks it from the cooler when it gets cool). Does the vernatherm require adjustment as the weather changes?

There are a couple of threads describing adding a pilot-controlled shutter onto the oil cooler, to block off the airflow when the oil is not warm enough. Looks like a few of the usual vendors including Vans sell these shutters. But what purpose do these shutters serve with the vernatherm controlling oil flow? Shouldn't the oil flow through the cooler be at a minimum if the oil itself is cool?

I suppose my oil temperature probe may be inaccurate too. Any good tips on how to measure its accuracy?