My crank was dynamically balanced, and rods balanced by Aircraft Specialties

I'm in the process of pairing assemblies to balance opposing reciprocating weights.

Dumb question...

Is there anything wrong with mixing and matching assemblies? I know rods and caps can't be swapped because they're honed as pairs, but is there anything else? Everything is numbered 1-4, but not sure this is anything but to ID them. Can you put the #2 rod with #1 piston with #3 piston pin?

FYI...this is a overhaul...some parts inspected/repaired and some replaced new.

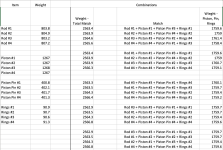

Attached are my current weights...

I'm in the process of pairing assemblies to balance opposing reciprocating weights.

Dumb question...

Is there anything wrong with mixing and matching assemblies? I know rods and caps can't be swapped because they're honed as pairs, but is there anything else? Everything is numbered 1-4, but not sure this is anything but to ID them. Can you put the #2 rod with #1 piston with #3 piston pin?

FYI...this is a overhaul...some parts inspected/repaired and some replaced new.

Attached are my current weights...

Attachments

Last edited: