Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clevis pin vs cotter pin

- Thread starter Webb

- Start date

The pin provides a rotational bearing surface. A cotter pin, being split into two halves, won’t allow quite as smooth a rotation. The washer suggestion is a good one; it will at least help keep the two arms of the cotter pin together in the rotation area.

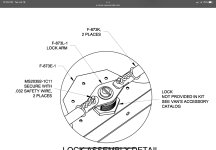

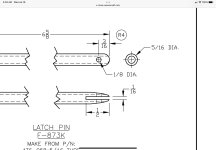

Good points but the connection is a clevis so the so a washer isn’t needed for a bearing surface or to hold the pin together since the clevis holes and the cotter pin diameter are 1/8”. This picture is more clear. Also at an 1/8”, the cotter pin halves make a smooth round so rotation should be smooth. The only downside I see is when splitting that large a cotter pin, it could put pressure on the clevis and cause binding.

You aren’t being snarky Pete. Builders often deviate from the plans. I would prefer to use a cotter pin instead of a wired clevis pin. Both work. Is one better? That’s why I reached out to the more experienced.

Attachments

Last edited:

The baggage door lock cam uses a 1/8” safety wired clevis pin to pivot on. I have some 1/8” stainless cotter pins. Any reason why I shouldn’t use a cotter pin instead?

A clevis pin was designed to handle a shear load and cotter pins where not.

BillL

Well Known Member

A clevis pin was designed to handle a shear load and cotter pins where not.

+1 Cotters are lower strength and higher hardness for loads and wear. For example take a clevis and cotter and try to cut them with some pliers. One is easy the other is certainly not.

A cotter pin, while being round also has two openings that act just like the blade on a block plane; Lots of wear. Further, I don;t think you are capturing all of the design intent here. They are securing the clevis so that it only rotates inside the steel part. Steel on steel should not have a major wear issue, but that is not the case with steel rotating on alum, which is what happens if the pin is not captured to the Alum part. I suspect this won't see a lot of use, beyond vibration, but pretty sure that is why they are using safety wire that way instead of a cotter pin.

Also agree with others that a cotter is just too soft for this application. Their only job is to keep a nut from loosening or a clevis pin from sliding out and they have a design goal of being easy to bend, which makes them inherently weak. They are not structural in any way shape or form. Take your 1/8 cotter pin and bend it (can probably do it with just your fingers) then try to bend the 1/8" clevis pin or a #6 screw (a little under 1/8" at it's minor diameter). HUGE difference.

Lots of folks reacting probably not because this is a major issue with a baggage door latch, but if you start to follow this approach to more critical areas, you end up with a poorly executed build. Substitutions like this can lead to major problems if the engineering is not fully understood. Not saying that I fully understand it, but do understand that deviations can create compromises.

Larry

Also agree with others that a cotter is just too soft for this application. Their only job is to keep a nut from loosening or a clevis pin from sliding out and they have a design goal of being easy to bend, which makes them inherently weak. They are not structural in any way shape or form. Take your 1/8 cotter pin and bend it (can probably do it with just your fingers) then try to bend the 1/8" clevis pin or a #6 screw (a little under 1/8" at it's minor diameter). HUGE difference.

Lots of folks reacting probably not because this is a major issue with a baggage door latch, but if you start to follow this approach to more critical areas, you end up with a poorly executed build. Substitutions like this can lead to major problems if the engineering is not fully understood. Not saying that I fully understand it, but do understand that deviations can create compromises.

Larry

Last edited:

Canadian_JOY

Well Known Member

In this instance there may be another design intent which hasn't yet been touched upon in this discussion.

This is the latch for a baggage door. In the category of airliner placards, this baggage area may wisely be placarded, "Use caution when opening as contents may have shifted during flight."

With this in mind, the Vans drawing shows safety wire with its twisted termination secured between the lock rod and the F873E1 plate. In this manner the ends of the safety wire cannot easily get snagged on contents of the baggage compartment.

In this installation the use of a cotter pin (and thin washer) would result in some potential for snagging on baggage. Even if the cotter pin ends are bent in a full butterfly, wrapped so the end of the cotter is bent in a circular fashion such that it terminates touching itself where the pin exits the clevis, there's still some potential for snagging.

The safety wire method, if done neatly, reduces the potential for snagging. Even so, I would still want to put a thin washer between the safety wire and locking rod just to provide a sacrificial surface rather than having the safety wire potentially wear on the locking rod.

This is the latch for a baggage door. In the category of airliner placards, this baggage area may wisely be placarded, "Use caution when opening as contents may have shifted during flight."

With this in mind, the Vans drawing shows safety wire with its twisted termination secured between the lock rod and the F873E1 plate. In this manner the ends of the safety wire cannot easily get snagged on contents of the baggage compartment.

In this installation the use of a cotter pin (and thin washer) would result in some potential for snagging on baggage. Even if the cotter pin ends are bent in a full butterfly, wrapped so the end of the cotter is bent in a circular fashion such that it terminates touching itself where the pin exits the clevis, there's still some potential for snagging.

The safety wire method, if done neatly, reduces the potential for snagging. Even so, I would still want to put a thin washer between the safety wire and locking rod just to provide a sacrificial surface rather than having the safety wire potentially wear on the locking rod.

The baggage door lock cam uses a 1/8” safety wired clevis pin to pivot on. I have some 1/8” stainless cotter pins. Any reason why I shouldn’t use a cotter pin instead?

You can try it out and let us know. This is experimental after all. If everybody follows the plan to the letter, every RV will look the same but they don't. The baggage door was probably the most frustrating build, other than the fuel tanks, so I followed the drawing as much as I could. I had to make modification to align the lock.

The points brought up are all good but I am going to disagree with them.

Pin is soft and easier to cut and bend….. It’s stainless and not soft steel which also makes it hard to bend. Also the diameter makes it hard to bend

Not designed to handle the sheer force…. It’s much stronger than the 3/16” aluminum it goes through. Probably a moot point since the cam lock’s force is probably a pound to move the locking pins. As far as wear, it’s low use (only when turning the lock) and only a quarter turn at that. Might take a few years to find out if it is wearing. On condition inspection, I would be inspecting and lubing the lock.

It can snag…… that is a potential however the lock is in the space between the outer and inner door which guards the cam from getting snagged. I plan to deviate from the plans and put a cover plate over the access hole just to keep junk from getting inside the door. Hence, no chance of snagging.

One point that wasn’t brought up is clearance. The cotter pin sticks out further. I checked but doesn’t catch on anything when the lock rotates. The clevis pin has a lower profile and doesn’t stick out as far.

At least I have an option if I can’t find clevis pins.

You guys are great. Looking for points of failure helps everyone build safer and better planes.

During this discussion, I thought about the splaying of the cotter pin could compress the clevis and bind the lock. This is why I’m going clevis pin.

Pin is soft and easier to cut and bend….. It’s stainless and not soft steel which also makes it hard to bend. Also the diameter makes it hard to bend

Not designed to handle the sheer force…. It’s much stronger than the 3/16” aluminum it goes through. Probably a moot point since the cam lock’s force is probably a pound to move the locking pins. As far as wear, it’s low use (only when turning the lock) and only a quarter turn at that. Might take a few years to find out if it is wearing. On condition inspection, I would be inspecting and lubing the lock.

It can snag…… that is a potential however the lock is in the space between the outer and inner door which guards the cam from getting snagged. I plan to deviate from the plans and put a cover plate over the access hole just to keep junk from getting inside the door. Hence, no chance of snagging.

One point that wasn’t brought up is clearance. The cotter pin sticks out further. I checked but doesn’t catch on anything when the lock rotates. The clevis pin has a lower profile and doesn’t stick out as far.

At least I have an option if I can’t find clevis pins.

You guys are great. Looking for points of failure helps everyone build safer and better planes.

During this discussion, I thought about the splaying of the cotter pin could compress the clevis and bind the lock. This is why I’m going clevis pin.

Last edited: