Was in the simulator shake, rattle and rollin’ all weekend. Today's edition is a perfect example of how technical questions get (hopefully) helpful answers - lots of lots of builder pics and replies. Exactly what this site is about!

Hope you got to spend some time with your RV! Have a nice eclipse! V/r,dr

VAF POSTS & RV NEWS THAT CAUGHT MY EYE.....dr:

—————————————————————————

What did you do w/your RV this weekend? (4/6-7/2024)

www.vansairforce.net

www.vansairforce.net

David Paule -3B Status

After climbing in and out of the cockpit too many times, I finally decided where to put the prop and mixture verniers and the carb heat control.

https://vansairforce.net/threads/rv-3b-daves-in-colorado.85658/page-15#post-1759356

7A RV Grin…GrinchF16

Got to fly a good friend of mine today. His grandad was an aeronautical engineer and his dad served in the USAF. He's always been fascinated by flight but never flown in anything like our mighty RV's. We both had a ball!!

vansairforce.net

vansairforce.net

Panel Porn…Becssc

Nearly done with phase 1. What a machine!

vansairforce.net

vansairforce.net

Modifications that you have Made to your RV-12 after Certification? E-LSA Only!

I was playing around with the 3D printer and made nut covers for the canopy bolts, kinda cleans it up a bit. I have a hex hole to accept the nut and they fit tight but still might use a dab of RTV. I'm still working on the print parameters. It will take 56 to do all the visible screws, weight gain 1/2 ounce.

vansairforce.net

vansairforce.net

Duplex Fuel Valve / Mounting Plate

For those who used a non-standard fuel valve such as the FS2020 Duplex valve in the -14 (it has a different bolt hole pattern to the stock FS20x2), how did you mount it?

I wasn’t planning to use the TS Flightlines setup as the cost is just too prohibitive with the exchange rate, and I understand this includes a modified mounting plate.

The stock mount plate is 0.032” so i was thinking of just making a plate up and match drilling the mounting and nutplate holes and bending a couple of flanges.

Keen to hear what other people have done.

www.vansairforce.net

www.vansairforce.net

Non-functioning brake.

Tried to go fly my 8A this morning, but the left side brake didn't work. Felt firm, but it didn't seem to keep the tire from rotating. At least not enough to get the plane to actually turn left. Had to turn 270 right to get back to the hangar.

So, back in the hanger tested it and it did hold well enough to keep me from being able to push the plane back by the tire when pressing. No noticeable leaks. Pads are still thick. Drained out some fluid and bled it. Push back out and no change, still couldn't get enough brake force to turn the plane to the left against the slight slope in front of the hangar.

vansairforce.net

vansairforce.net

Prop Oil line interference

All, I installed my prop oil line per the lycoming manual. My case is a narrow deck 360 so I do not have the boss mount for the standard clip. I added some adel clamps and a zip tie pad. The line runs right past the plane power alternator and I have to have the alternator at max tension to keep from hitting the line. See attached pics. I thought about bending the line to hug the case a little tighter but I don’t think that will give me a ton of additional clearance. Any ideas?

vansairforce.net

vansairforce.net

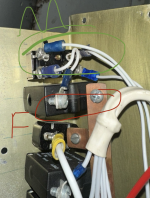

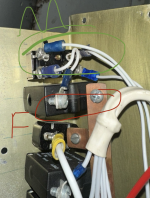

Please help me understand my alternator field switch circuit configuration

I am troubleshooting an issue preventing the correct voltage from reaching my B&C voltage regulator. In trouble shooting the alternator field switch in the panel, I found it wired as shown in the photo. The “M” is the master switch and the “F” is the field switch with is actually a 5a toggle breaker.

I am trying to understand why the field switch is connect to the bus and the master rather than being connected directly to the voltage regulator as shown in the recommended wiring diagram from B&C.

Any thoughts on this installation?

www.vansairforce.net

www.vansairforce.net

Progress: climbak -4 fastback

Very little progress the last few weeks. The canopy supplier wants to make a new one that has a better profile so still waiting on that before I can start final fitting of the bulkheads and cleco them in place for the skin fitting. Made a few bulkhead supports that are just roughed out on shaping. Been making some small parts like new throttle lever and templates for the bulkhead doublers. The rest of my time has been research, testing and making adjustments to one of the museum planes. Also scheming up another museum warbird project because I can't sit still and if I'm stuck waiting and not building, then I start planning.

www.vansairforce.net

www.vansairforce.net

OFF TOPIC:

PS: Older issues of the ‘VAF News’ can be found at:

www.vansairforce.net

www.vansairforce.net

Hope you got to spend some time with your RV! Have a nice eclipse! V/r,dr

VAF POSTS & RV NEWS THAT CAUGHT MY EYE.....dr:

—————————————————————————

What did you do w/your RV this weekend? (4/6-7/2024)

What did you do w/your RV this weekend? (4/6-7/2024)

....getting this weekend's thread started. Happy weekend, everyone! v/r,dr

David Paule -3B Status

After climbing in and out of the cockpit too many times, I finally decided where to put the prop and mixture verniers and the carb heat control.

https://vansairforce.net/threads/rv-3b-daves-in-colorado.85658/page-15#post-1759356

7A RV Grin…GrinchF16

Got to fly a good friend of mine today. His grandad was an aeronautical engineer and his dad served in the USAF. He's always been fascinated by flight but never flown in anything like our mighty RV's. We both had a ball!!

7A RV Grin

Got to fly a good friend of mine today. His grandad was an aeronautical engineer and his dad served in the USAF. He's always been fascinated by flight but never flown in anything like our mighty RV's. We both had a ball!!

Panel Porn…Becssc

Nearly done with phase 1. What a machine!

Show us your RV-14 panel

Hi all, I thought I might share my progress on the RV-14 panel. I have fabricated some backlit "sub-panels" and I am very excited with the results! It's all homemade, using laser engraver paint, acrylic, and flexible LED strings. Wow….that’s very nice!!

Modifications that you have Made to your RV-12 after Certification? E-LSA Only!

I was playing around with the 3D printer and made nut covers for the canopy bolts, kinda cleans it up a bit. I have a hex hole to accept the nut and they fit tight but still might use a dab of RTV. I'm still working on the print parameters. It will take 56 to do all the visible screws, weight gain 1/2 ounce.

Modifications that you have Made to your RV-12 after Certification? E-LSA Only!

Maybe, Jim —- or maybe he REALLY made some mods!😝

Duplex Fuel Valve / Mounting Plate

For those who used a non-standard fuel valve such as the FS2020 Duplex valve in the -14 (it has a different bolt hole pattern to the stock FS20x2), how did you mount it?

I wasn’t planning to use the TS Flightlines setup as the cost is just too prohibitive with the exchange rate, and I understand this includes a modified mounting plate.

The stock mount plate is 0.032” so i was thinking of just making a plate up and match drilling the mounting and nutplate holes and bending a couple of flanges.

Keen to hear what other people have done.

Duplex Fuel Valve / Mounting Plate

For those who used a non-standard fuel valve such as the FS2020 Duplex valve in the -14 (it has a different bolt hole pattern to the stock FS20x2), how did you mount it? I wasn’t planning to use the TS Flightlines setup as the cost is just too prohibitive with the exchange rate, and I...

Non-functioning brake.

Tried to go fly my 8A this morning, but the left side brake didn't work. Felt firm, but it didn't seem to keep the tire from rotating. At least not enough to get the plane to actually turn left. Had to turn 270 right to get back to the hangar.

So, back in the hanger tested it and it did hold well enough to keep me from being able to push the plane back by the tire when pressing. No noticeable leaks. Pads are still thick. Drained out some fluid and bled it. Push back out and no change, still couldn't get enough brake force to turn the plane to the left against the slight slope in front of the hangar.

Non-functioning brake.

Tried to go fly my 8A this morning, but the left side brake didn't work. Felt firm, but it didn't seem to keep the tire from rotating. At least not enough to get the plane to actually turn left. Had to turn 270 right to get back to the hangar. So, back in the hanger tested it and it did hold...

Prop Oil line interference

All, I installed my prop oil line per the lycoming manual. My case is a narrow deck 360 so I do not have the boss mount for the standard clip. I added some adel clamps and a zip tie pad. The line runs right past the plane power alternator and I have to have the alternator at max tension to keep from hitting the line. See attached pics. I thought about bending the line to hug the case a little tighter but I don’t think that will give me a ton of additional clearance. Any ideas?

Prop Oil line interference

All, I installed my prop oil line per the lycoming manual. My case is a narrow deck 360 so I do not have the boss mount for the standard clip. I added some adel clamps and a zip tie pad. The line runs right past the plane power alternator and I have to have the alternator at max tension to keep...

Please help me understand my alternator field switch circuit configuration

I am troubleshooting an issue preventing the correct voltage from reaching my B&C voltage regulator. In trouble shooting the alternator field switch in the panel, I found it wired as shown in the photo. The “M” is the master switch and the “F” is the field switch with is actually a 5a toggle breaker.

I am trying to understand why the field switch is connect to the bus and the master rather than being connected directly to the voltage regulator as shown in the recommended wiring diagram from B&C.

Any thoughts on this installation?

Please help me understand my alternator field switch circuit configuration

I am troubleshooting an issue preventing the correct voltage from reaching my B&C voltage regulator. In trouble shooting the alternator field switch in the panel, I found it wired as shown in the photo. The “M” is the master switch and the “F” is the field switch with is actually a 5a toggle...

Progress: climbak -4 fastback

Very little progress the last few weeks. The canopy supplier wants to make a new one that has a better profile so still waiting on that before I can start final fitting of the bulkheads and cleco them in place for the skin fitting. Made a few bulkhead supports that are just roughed out on shaping. Been making some small parts like new throttle lever and templates for the bulkhead doublers. The rest of my time has been research, testing and making adjustments to one of the museum planes. Also scheming up another museum warbird project because I can't sit still and if I'm stuck waiting and not building, then I start planning.

RV-4 #4175 Fastback Conversion

My 4 is down for a bit for a several little projects, like elevator reskinning due to some cracking, adding a light to the tail, possibly electric trim, fiberglass repair due to some less than perfect fits over the years, etc. While it's down, I decided to make it way worse for time and money...

OFF TOPIC:

PS: Older issues of the ‘VAF News’ can be found at:

Doug's Area ....The VAF News & my flying resume.

Pushed out every now and then.