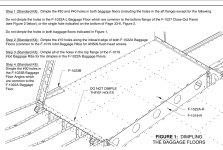

I’m baffled as to how I’m supposed to dimple these holes. They are right next to the side skin on the passenger side and in front of and behind the baggage door.

Unless somebody has some trick I’ve never imagined I’m going to have to drill out the 25 or so skin rivets and take these out in order to get them dimpled.

Unless somebody has some trick I’ve never imagined I’m going to have to drill out the 25 or so skin rivets and take these out in order to get them dimpled.

Last edited: