kbalch

Well Known Member

I'm beginning to think seriously about engine options (I can already taste the OSH special...) and I've been wondering whether the Thunderbolt is worth its premium over the standard Lycoming.

When I built my -8 so many years ago, I ordered an IO-360 from Aerosport Power and was very happy with both the engine and the service that I received from Bart. I ordered one Lightspeed EI and Airflow Performance FI and paid, as I recall, $25K.

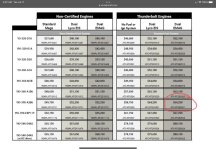

Aerosport's price today for an IO-390 is north of $41K vs. Van's price of $35K with one EI (less the prop discount and any further show special). Van's Thunderbolt price is $38.6K with one EI (less the same discounts previously mentioned).

So, assuming that I don't care about pretty colors on an engine that (hopefully) almost nobody will ever see, why does the Thunderbolt merit a $3K+ premium? I understand that the components are balanced to a greater degree than the standard Lyc, but it can't be that much smoother, can it? Really?!?

Naturally, I'm not trying to start a war and I'd rather not provoke anybody's confirmation bias, but I'm definitely open-minded about it and (as always!) willing to be taught something new. Have at it, boys...

When I built my -8 so many years ago, I ordered an IO-360 from Aerosport Power and was very happy with both the engine and the service that I received from Bart. I ordered one Lightspeed EI and Airflow Performance FI and paid, as I recall, $25K.

Aerosport's price today for an IO-390 is north of $41K vs. Van's price of $35K with one EI (less the prop discount and any further show special). Van's Thunderbolt price is $38.6K with one EI (less the same discounts previously mentioned).

So, assuming that I don't care about pretty colors on an engine that (hopefully) almost nobody will ever see, why does the Thunderbolt merit a $3K+ premium? I understand that the components are balanced to a greater degree than the standard Lyc, but it can't be that much smoother, can it? Really?!?

Naturally, I'm not trying to start a war and I'd rather not provoke anybody's confirmation bias, but I'm definitely open-minded about it and (as always!) willing to be taught something new. Have at it, boys...