Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RV-3 Plans - 'Clarifications'

- Thread starter Andy Hill

- Start date

David Paule

Well Known Member

Aileron Ribs A304

These fit nicely into the A302 aileron spars and seem to have the correct taper. However, when this assembly (spar and the two end ribs, all clamped together) is inserted into the skin, once the assembly is located for best fit, the spar is about 1/4" forward of its correct location.

My first thought was that this might make fitting the flap somewhat easier. But there's not enough edge distance for the bottom skin on the spar; I'm going to have to do some surgery on the ribs to get the spar to the proper location. I haven't decided if that means reforming the ribs, changing the forward flange (the one the spar attaches to) or something else.

Edit - Turns out that the taper was off a bit. The aft end is too wide. When I fixed that the spar was in the right position.

Also, initially, it looked as if the ribs were a tad too deep in the front and were pushing the spar flanges out a bit. That, though, was merely the vinyl. When I removed it from the ribs and the spar at the ends, the ribs fit much better. Vinyl isn't very thick but it does have some thickness, something around .0025 inches, more or less, and it adds up.

Dave

RV-3 - If you're done thinking and ready to drill... that means you're not done thinking.

These fit nicely into the A302 aileron spars and seem to have the correct taper. However, when this assembly (spar and the two end ribs, all clamped together) is inserted into the skin, once the assembly is located for best fit, the spar is about 1/4" forward of its correct location.

My first thought was that this might make fitting the flap somewhat easier. But there's not enough edge distance for the bottom skin on the spar; I'm going to have to do some surgery on the ribs to get the spar to the proper location. I haven't decided if that means reforming the ribs, changing the forward flange (the one the spar attaches to) or something else.

Edit - Turns out that the taper was off a bit. The aft end is too wide. When I fixed that the spar was in the right position.

Also, initially, it looked as if the ribs were a tad too deep in the front and were pushing the spar flanges out a bit. That, though, was merely the vinyl. When I removed it from the ribs and the spar at the ends, the ribs fit much better. Vinyl isn't very thick but it does have some thickness, something around .0025 inches, more or less, and it adds up.

Dave

RV-3 - If you're done thinking and ready to drill... that means you're not done thinking.

Last edited:

Andy Hill

Well Known Member

Control Bearings

To save some confusion later on, suggest write on your plans the 'Bearing Types'. The plans sometimes omit this, or use an outdated part type - the packing lists do make it clear. The male bearings are:

To save some confusion later on, suggest write on your plans the 'Bearing Types'. The plans sometimes omit this, or use an outdated part type - the packing lists do make it clear. The male bearings are:

- Elevators: 2x MD3614M each

- Rudder: MD3614M (top) MD3616M (bottom - longer bearing)

- Aileron Pushrods (large ones): 2x MD3614M each

- Elevator Pushrod (large one): 2x MD3616M (longer bearing)

David Paule

Well Known Member

Aileron Assembly Sequence

Here are two tips, learned the hard way:

1. Drill, dimple and rivet the stiffeners to the skins BEFORE tightening the trailing edge bend. The layout provides dimensions which are okay for this.

2. Drill and rivet the pipe counterbalance to the nose ribs BEFORE riveting the nose ribs to the spar.

Dave

Here are two tips, learned the hard way:

1. Drill, dimple and rivet the stiffeners to the skins BEFORE tightening the trailing edge bend. The layout provides dimensions which are okay for this.

2. Drill and rivet the pipe counterbalance to the nose ribs BEFORE riveting the nose ribs to the spar.

Dave

David Paule

Well Known Member

Examine Those Aileron Nose Ribs

Looks like Van's has a bad bunch of them. They arrive poorly formed and sometimes cracked at the middle of the forward flange. Here's an example:

The last aileron I ordered had one bad one. These are part number A-303 L or R.

Dave

Looks like Van's has a bad bunch of them. They arrive poorly formed and sometimes cracked at the middle of the forward flange. Here's an example:

The last aileron I ordered had one bad one. These are part number A-303 L or R.

Dave

David Paule

Well Known Member

Wing Inspection Holes - Inboard

Here's what I wish I'd done for the inspection holes on the bottom of the wings on my RV-3B. The plans shows the single inboard inspection hole, which I X'd out with a red X.

Instead, if we skip that one and put in two, one on each of the adjacent rib bays like I've shown in green, we'd have much better access to both riveting on that bottom skin and removing or reinstalling the tanks some day.

If that photo's gone away try this alternate hosting site.

If you DON'T make this change, then at least reverse the flange direction on the rib to the outboard (left in the photo) side of the inspection hole, to make it easier to rivet. Change the W-339L to W-339R.

Dave

Here's what I wish I'd done for the inspection holes on the bottom of the wings on my RV-3B. The plans shows the single inboard inspection hole, which I X'd out with a red X.

Instead, if we skip that one and put in two, one on each of the adjacent rib bays like I've shown in green, we'd have much better access to both riveting on that bottom skin and removing or reinstalling the tanks some day.

If that photo's gone away try this alternate hosting site.

If you DON'T make this change, then at least reverse the flange direction on the rib to the outboard (left in the photo) side of the inspection hole, to make it easier to rivet. Change the W-339L to W-339R.

Dave

Last edited:

David Paule

Well Known Member

Inboard End of Spar

There are a couple things to do at the inboard ends of the main wing spars, in the blue box in the photo:

Hint: It's a lot easier to do these before assembling the spar into the wing frame. Do these first. They won't interfere with any work down the road.

(If the photo doesn't show up try this alternate link.

Dave

There are a couple things to do at the inboard ends of the main wing spars, in the blue box in the photo:

Hint: It's a lot easier to do these before assembling the spar into the wing frame. Do these first. They won't interfere with any work down the road.

(If the photo doesn't show up try this alternate link.

Dave

David Paule

Well Known Member

Longeron Clamps on SK-42

I made the vertical leg of my longeron clamps 1/2" per SK-42. Here's SK-42 so you can see this.

On the F-305 seat bulkhead, it looks like a .090 shim will do the trick. When I clamped the longeron, I realized that I couldn't get the longeron to touch the jig; there's a bit of a gap there at the outboard corner. In this photo you can't see the gap, but you can see the clamp being in face-to-face contact with the longeron.

I recommend that the 3/8 to 1/2 inch dimension be increased to 1/2 to 5/8 inch.

Photos are also hosted here and here.

Dave

I made the vertical leg of my longeron clamps 1/2" per SK-42. Here's SK-42 so you can see this.

On the F-305 seat bulkhead, it looks like a .090 shim will do the trick. When I clamped the longeron, I realized that I couldn't get the longeron to touch the jig; there's a bit of a gap there at the outboard corner. In this photo you can't see the gap, but you can see the clamp being in face-to-face contact with the longeron.

I recommend that the 3/8 to 1/2 inch dimension be increased to 1/2 to 5/8 inch.

Photos are also hosted here and here.

Dave

David Paule

Well Known Member

Tailspring Mount Geometry to F-311 Bulkhead

I'm in the middle of attaching the tailspring mount to the aft two bulkheads. This is the geometry that I'm using at the F-311 bulkhead. The dimensions came from drawings 16, 26 and 28.

Dave

I'm in the middle of attaching the tailspring mount to the aft two bulkheads. This is the geometry that I'm using at the F-311 bulkhead. The dimensions came from drawings 16, 26 and 28.

Dave

Last edited:

David Paule

Well Known Member

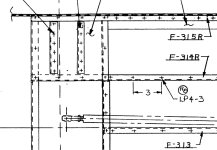

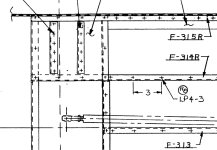

F-315 Seat Bulkhead Sequence

I figured I'd better add a few notes to the discussion on my VAF blog about riveting the F-315 seat rib to the F-303 spar bulkhead since not everyone will see that.

I think that the best way to do this is to rivet the rivets shown in the red oval while the aft bulkhead is still separate from the forward one. At this point it's a simple matter of back-riveting the joint, and the seat rib can be bent away for clearance. The bulkhead won't be drilled for the F-303F splice strip or the F-303E side plates yet.

After this, the bulkheads can be joined with the F-303F splice strip, but the F-303E side plates ought to await having the bulkhead on the jig with the longerons. Then the side plates can be drilled through the F-315 seat ribs webs at the blue oval. Once that's done, the seat ribs can be formed so that the ribs have a joggle around the side plates by using a flange fluting tool.

I failed to do that and went ahead and riveted the F-303F splice strip on too early. This was handy for jigging up the bulkheads and the longerons. When I wanted to rivet the F-315 seat ribs to the bulkhead, I discovered that it was going to be difficult. You can read about that in post #306.

I followed this sequence for the overall seat rib installation:

1. Uncleco and remove the F-315 seat ribs.

2. Uncleco and remove the F-303E side plates.

3. Countersink the end plates.

4. Uncleco and remove the F-313 center seat rib.

5. Uncleco and remove the F-304 bulkhead.

6. Uncleco and remove the F-314 seat ribs.

7. Rivet the F-304 bulkhead to the F-313 center seat rib.

8. Cleco the F-304 bulkhead to the F-305 seat bulkhead.

9. Rivet the F-304 bulkhead to the F-305 seat bulkhead.

10. Cleco the F-314 seat ribs in place.

11. Rivet the mixer brackets to the F-314 seat ribs. In my case, some of those rivets also went through the F-304 bulkhead or the flanges already riveted to the F-303 aft bulkhead, and I left these unriveted for this step.

12. Rivet the F-304 bulkhead to the F-314 seat ribs, including the mixer brackets.

13. Rivet the F-314 seat ribs to the F-303 aft spar bulkhead, including the mixer brackets. For some reason this was harder than I expected, due to the various other parts in the area interfering with it.

14. Rivet the F-314 seat ribs to the F-305 seat bulkhead.

15. Rivet the F-315 outer seat ribs to the F-303 aft bulkhead.

16. Rivet the F-303E side plates to the F-303 spar bulkhead and the F-315 seat ribs.

I figured I'd better add a few notes to the discussion on my VAF blog about riveting the F-315 seat rib to the F-303 spar bulkhead since not everyone will see that.

I think that the best way to do this is to rivet the rivets shown in the red oval while the aft bulkhead is still separate from the forward one. At this point it's a simple matter of back-riveting the joint, and the seat rib can be bent away for clearance. The bulkhead won't be drilled for the F-303F splice strip or the F-303E side plates yet.

After this, the bulkheads can be joined with the F-303F splice strip, but the F-303E side plates ought to await having the bulkhead on the jig with the longerons. Then the side plates can be drilled through the F-315 seat ribs webs at the blue oval. Once that's done, the seat ribs can be formed so that the ribs have a joggle around the side plates by using a flange fluting tool.

I failed to do that and went ahead and riveted the F-303F splice strip on too early. This was handy for jigging up the bulkheads and the longerons. When I wanted to rivet the F-315 seat ribs to the bulkhead, I discovered that it was going to be difficult. You can read about that in post #306.

I followed this sequence for the overall seat rib installation:

1. Uncleco and remove the F-315 seat ribs.

2. Uncleco and remove the F-303E side plates.

3. Countersink the end plates.

4. Uncleco and remove the F-313 center seat rib.

5. Uncleco and remove the F-304 bulkhead.

6. Uncleco and remove the F-314 seat ribs.

7. Rivet the F-304 bulkhead to the F-313 center seat rib.

8. Cleco the F-304 bulkhead to the F-305 seat bulkhead.

9. Rivet the F-304 bulkhead to the F-305 seat bulkhead.

10. Cleco the F-314 seat ribs in place.

11. Rivet the mixer brackets to the F-314 seat ribs. In my case, some of those rivets also went through the F-304 bulkhead or the flanges already riveted to the F-303 aft bulkhead, and I left these unriveted for this step.

12. Rivet the F-304 bulkhead to the F-314 seat ribs, including the mixer brackets.

13. Rivet the F-314 seat ribs to the F-303 aft spar bulkhead, including the mixer brackets. For some reason this was harder than I expected, due to the various other parts in the area interfering with it.

14. Rivet the F-314 seat ribs to the F-305 seat bulkhead.

15. Rivet the F-315 outer seat ribs to the F-303 aft bulkhead.

16. Rivet the F-303E side plates to the F-303 spar bulkhead and the F-315 seat ribs.

David Paule

Well Known Member

A Firewall Detail and a Spar Bulkhead Fitting Issue

There are two areas in the assembly of the firewall and the spar bulkhead build-up where a builder might make an error like I did.

The first is on the bottom of the firewall. There's a 3/4 x 3/4 x 1/8 angle that gets riveted to the firewall. It should NOT be flush to the flange. Instead, don't forget to allow a .040 gap for the F-321 forward belly skin.

Here's what it will be when you're done:

Yeah, I didn't pay enough attention there and made mine flush. I added some room for the skin by making a short piece of .040, beveling the forward edge, and used a clamp, with a block of wood against the firewall, to force it in. The flange is ductile and bent up to allow the strip to fit in.

It didn't take much tooling. The hammer let me tap the flange flat again and that was easy. The marker let me keep track of where I was, and the mirror was handy to make sure the .040 strip was seated.

The second area is the bottom of the F-303 spar bulkhead. This doesn't really affect the spar bulkhead itself, but the lower longeron parts and the F-312 firewall ribs need to be made to fit this correctly. The main thing is the height of these parts. They need to be flush with wherever the F-321 forward firewall skin lays on the spar bulkhead assembly as it's being built. I had to redo mine, since I didn't get it right.

Remember that right in the center, the seat belly skins overlap at the dihedral break. That won't affect the lower longeron and F-312 fit-up, but it will affect the F-321 forward belly skin itself, which has a compound curve there.

Here's how it should be. (And here I'm referring only to the forward lower longerons).

Dave

There are two areas in the assembly of the firewall and the spar bulkhead build-up where a builder might make an error like I did.

The first is on the bottom of the firewall. There's a 3/4 x 3/4 x 1/8 angle that gets riveted to the firewall. It should NOT be flush to the flange. Instead, don't forget to allow a .040 gap for the F-321 forward belly skin.

Here's what it will be when you're done:

Yeah, I didn't pay enough attention there and made mine flush. I added some room for the skin by making a short piece of .040, beveling the forward edge, and used a clamp, with a block of wood against the firewall, to force it in. The flange is ductile and bent up to allow the strip to fit in.

It didn't take much tooling. The hammer let me tap the flange flat again and that was easy. The marker let me keep track of where I was, and the mirror was handy to make sure the .040 strip was seated.

The second area is the bottom of the F-303 spar bulkhead. This doesn't really affect the spar bulkhead itself, but the lower longeron parts and the F-312 firewall ribs need to be made to fit this correctly. The main thing is the height of these parts. They need to be flush with wherever the F-321 forward firewall skin lays on the spar bulkhead assembly as it's being built. I had to redo mine, since I didn't get it right.

Remember that right in the center, the seat belly skins overlap at the dihedral break. That won't affect the lower longeron and F-312 fit-up, but it will affect the F-321 forward belly skin itself, which has a compound curve there.

Here's how it should be. (And here I'm referring only to the forward lower longerons).

Dave

David Paule

Well Known Member

Instrument Panel Dimensions

The drawing isn't accurate. Here's what I started with. Then I used some curves and faired it from there. Seems to be okay.

0 and 9.67 or 9.65

1 and 9.65

2 and 9.56

3 and 9.38

4 and 9.12

5 and 8.77

6 and 8.33

7 and 7.82

8 and 7.18

9 and 6.37.

The remainder are fine.

I made my panel 1/2" taller than stock, all at the bottom, and still had 3.7" to the stick. That's without a stick grip, though. YMMV. The dimensions above are to the stock panel bottom, not my extension.

Dave

The drawing isn't accurate. Here's what I started with. Then I used some curves and faired it from there. Seems to be okay.

0 and 9.67 or 9.65

1 and 9.65

2 and 9.56

3 and 9.38

4 and 9.12

5 and 8.77

6 and 8.33

7 and 7.82

8 and 7.18

9 and 6.37.

The remainder are fine.

I made my panel 1/2" taller than stock, all at the bottom, and still had 3.7" to the stick. That's without a stick grip, though. YMMV. The dimensions above are to the stock panel bottom, not my extension.

Dave

David Paule

Well Known Member

Aft Deck

The F-319 aft deck has two access and lightening holes and one clearance hole.

The clearance hole is the aft rectangular one, on the right of the part here on drawing 22. I haven't figured out if the left and center holes are functional or intended for access. So far I don't see anything that suggests that the left and center holes are functional. The rightmost hole allows for the elevator bellcrank, as shown on drawing 26.

The positioning of the three holes should be determined after the fuselage is assembled and the horizontal stabilizer fitted in place. It doesn't need to be completely aligned or mounted for this, you're ensuring that you have solid material where the forward stabilizer spar attachment goes. But fuselages vary and yours might - or might not - be exactly per the plans. Mine wasn't. And the plans for this part might - or might not - be exactly correct.

Incidentally, I'm sorry that so many of my previous images have been lost.

Dave

The F-319 aft deck has two access and lightening holes and one clearance hole.

The clearance hole is the aft rectangular one, on the right of the part here on drawing 22. I haven't figured out if the left and center holes are functional or intended for access. So far I don't see anything that suggests that the left and center holes are functional. The rightmost hole allows for the elevator bellcrank, as shown on drawing 26.

The positioning of the three holes should be determined after the fuselage is assembled and the horizontal stabilizer fitted in place. It doesn't need to be completely aligned or mounted for this, you're ensuring that you have solid material where the forward stabilizer spar attachment goes. But fuselages vary and yours might - or might not - be exactly per the plans. Mine wasn't. And the plans for this part might - or might not - be exactly correct.

Incidentally, I'm sorry that so many of my previous images have been lost.

Dave

The two access holes allow you to access the rudder cable where they exit the fuselage skin, the elevator torque tube at that end, the tailwheel spring retaining bolt ( I?m pretty sure) and any other wiring you may have going to the tail. Also allows you to inspect all the rivets in that area. Which is not a bad idea since those skins can take some abuse from the tailwheel.

David Paule

Well Known Member

Exactly. They allow access but the precise position isn't necessary for anything to function.

Dave

Dave

Clarification on Center Section Rear Spar Attachment

I am reviving an old RV-3 project that has been dormant for years. I need to implement to two change notices. My wings are the Type I. In looking at CN-1, it suggests there were two types of rear spar attachment pieces, the older one was for kits supplied before Sept. 1981 and calls for a 1" x 1" x 1/8" 6061-T6 angle attached to F-305. The newer kits called for a 1.25" x 1.25" x 3/16" 6061-T-6 angle. My plans and kit called for a 1.25" x 3/16" 2024-T4 bar instead of an angle. My piece is clecoed in right now so I can easily change it but after looking at pictures on this forum from some of your projects it looked like a lot of you also had bar instead of angle. Any thoughts on which is correct or at least which is preferred?

Bob Anderson (Chillibob)

I am reviving an old RV-3 project that has been dormant for years. I need to implement to two change notices. My wings are the Type I. In looking at CN-1, it suggests there were two types of rear spar attachment pieces, the older one was for kits supplied before Sept. 1981 and calls for a 1" x 1" x 1/8" 6061-T6 angle attached to F-305. The newer kits called for a 1.25" x 1.25" x 3/16" 6061-T-6 angle. My plans and kit called for a 1.25" x 3/16" 2024-T4 bar instead of an angle. My piece is clecoed in right now so I can easily change it but after looking at pictures on this forum from some of your projects it looked like a lot of you also had bar instead of angle. Any thoughts on which is correct or at least which is preferred?

Bob Anderson (Chillibob)

David Paule

Well Known Member

I think this is probably a question for Van's. Without knowing more about the joint between the wing spar and the F-305 carry-through, it's hard to comment. But I can confirm that my RV-3B does use the flat 2024 bar.

Dave

Dave

David Paule

Well Known Member

Well, I am, and here's my VAF blog. I'm going back out the the shop again in a few minutes. Wings mostly done, control surfaces done, tail done, fuselage past the canoe stage, working on the canopy installation now.

There's one in Central CA and one down under that I know of. There are a couple others, too, scattered around.

Dave

There's one in Central CA and one down under that I know of. There are a couple others, too, scattered around.

Dave

Chilibob.

I am building a 3B. Almost done. Concerning the rear spar carry through there have been issues. The design I believe calls for a 1.25 X 3/16 bar. This can cause edge distance issues when drilling hole for attaching wings. Many comments from builders suggested going to a 1.75 X 3/16 bar which is what I did. Worked out great.

Bob Grigsby

Hunkered/Sheltered in place

Los Altos Ca.

J3 Cub. Down for annual

3B close. I think

I am building a 3B. Almost done. Concerning the rear spar carry through there have been issues. The design I believe calls for a 1.25 X 3/16 bar. This can cause edge distance issues when drilling hole for attaching wings. Many comments from builders suggested going to a 1.75 X 3/16 bar which is what I did. Worked out great.

Bob Grigsby

Hunkered/Sheltered in place

Los Altos Ca.

J3 Cub. Down for annual

3B close. I think

Clarification on Center Section Rear Spar Attachment

RVBob,

Glad to know someone else in addition to David is still working on a RV-3B. Did you use the same single row of rivets to attach the 1.75" x 3/16" bar as the plans called for for the 1.25" bar? Any interferences as a result of the extra width?

Chillibob

RVBob,

Glad to know someone else in addition to David is still working on a RV-3B. Did you use the same single row of rivets to attach the 1.75" x 3/16" bar as the plans called for for the 1.25" bar? Any interferences as a result of the extra width?

Chillibob

New to the forum with a used RV-3

Gentleman,

I just bought an RV-3 on eBay. It's complete with only some parts missing. the previous owner started repairs and the spar mod. I may need some of the original plans (control stick and flap controls) for the early aircraft. Mine is serial #454. I have the thumb drive Vans sells but it covers the "B" model mostly. Is there a good sorce for the early plans? Thanks.

Gentleman,

I just bought an RV-3 on eBay. It's complete with only some parts missing. the previous owner started repairs and the spar mod. I may need some of the original plans (control stick and flap controls) for the early aircraft. Mine is serial #454. I have the thumb drive Vans sells but it covers the "B" model mostly. Is there a good sorce for the early plans? Thanks.

JohnTod,

I started building from plans number 489 and still have the old plans so if you have any questions about the old plans let me know. My wings started in 1977 and my fuselage was started around 1984. Just retired recently so I am trying to finish the project. Having fun but a severe challenge with so may changes.

Bob (Chillibob)

I started building from plans number 489 and still have the old plans so if you have any questions about the old plans let me know. My wings started in 1977 and my fuselage was started around 1984. Just retired recently so I am trying to finish the project. Having fun but a severe challenge with so may changes.

Bob (Chillibob)

Lufthans

Well Known Member

Fuselage rivet spacing and double rivet line at F-305?

Russell kindly pointed out that my bought aircraft only has one rivet line at the F-305 bulkhead, where it should have two. And that the rivets along the stiffeners on the rear fuse seemed to have the wrong spacing.

So I got out my plans, and am confused.

My plans set is dated 11-25-1984, and when I compare sheets 21 and 22 (forward and rear fuselage) against sheet 23 (Fuselage skins and rivets), things don't seem to add up. See attachments

(My plane seems to have been built according to sheets 21 and 22, by the way)

Anyone who can shed light on this one? Thanks!

P.S. I have been looking at photos of RV-3's and have found both versions to exist. Although the double rivet line with 1-1/4" rivet spacing seems to be in the majority. Zooming in on this photo though shows what seems to be a single rivet line, and 1" rivet spacing along the bottom edge of the aft fuselage. https://imgbb.com/VWBJb1R ( https://i.ibb.co/8D8NGCq/CCTG-and-MIRV.jpg)

Russell kindly pointed out that my bought aircraft only has one rivet line at the F-305 bulkhead, where it should have two. And that the rivets along the stiffeners on the rear fuse seemed to have the wrong spacing.

So I got out my plans, and am confused.

My plans set is dated 11-25-1984, and when I compare sheets 21 and 22 (forward and rear fuselage) against sheet 23 (Fuselage skins and rivets), things don't seem to add up. See attachments

(My plane seems to have been built according to sheets 21 and 22, by the way)

Anyone who can shed light on this one? Thanks!

P.S. I have been looking at photos of RV-3's and have found both versions to exist. Although the double rivet line with 1-1/4" rivet spacing seems to be in the majority. Zooming in on this photo though shows what seems to be a single rivet line, and 1" rivet spacing along the bottom edge of the aft fuselage. https://imgbb.com/VWBJb1R ( https://i.ibb.co/8D8NGCq/CCTG-and-MIRV.jpg)

Last edited:

David Paule

Well Known Member

Here is how I did my plane there. The forward row of rivets is for the skin to skin joint, just the skins, while the aft row is for both the skins to the bulkhead.

I used -3 rivets at 1" spacing, I think, for all the side skin joints, but as you can see from the photo, I also glued the joints.

The wooden parts are work platforms so that I can work inside. They remove easily.

Dave

I used -3 rivets at 1" spacing, I think, for all the side skin joints, but as you can see from the photo, I also glued the joints.

The wooden parts are work platforms so that I can work inside. They remove easily.

Dave

HFS

Well Known Member

Plans Clarification

Van in his "formative" years quite often forgot (neglected) to update all drawings as progressive refinements were made. Case in point - If you do a (close) check for the spacing for the fuel tank attach holes you will find at least 3 different "offerings" - in my case I called a friend who had QB wings and asked him what his spacing was. IIRC - it was choice #2 (right in the middle), so that is what I used.

In your particular case I would refer you to the builder's manual (which you may or may not have) that states on Page 8-11 Fuselage the following: "You will notice from DWG 23 that nearly all lap joints of skins fore-to-aft use double rows of rivets. This offers very strong joints through the use of small rivets moderately spaced."

I have built an early -4, a Harmon Rocket (same plans basically), and now a -3B but from the earlier plans (S/N 11226 - 1993), so I am quite familiar with the vagaries of Van's plans set. What I have always done to "break the tie" among differing plans specs, is to evaluate them and then use the one that offers the most effective structural option - read "most rivets".

I am not familiar with any airframes built before the drawing set we have (11-25/28-1984), so I can't speak to the "correctness" of your build - but it wouldn't surprise me if yours was built according to the plans in effect at that time.

However, having said that, my plans don't show any revisions on DRG 23 that might indicate an earlier single row rivet pattern.

YMMV

HFS

Van in his "formative" years quite often forgot (neglected) to update all drawings as progressive refinements were made. Case in point - If you do a (close) check for the spacing for the fuel tank attach holes you will find at least 3 different "offerings" - in my case I called a friend who had QB wings and asked him what his spacing was. IIRC - it was choice #2 (right in the middle), so that is what I used.

In your particular case I would refer you to the builder's manual (which you may or may not have) that states on Page 8-11 Fuselage the following: "You will notice from DWG 23 that nearly all lap joints of skins fore-to-aft use double rows of rivets. This offers very strong joints through the use of small rivets moderately spaced."

I have built an early -4, a Harmon Rocket (same plans basically), and now a -3B but from the earlier plans (S/N 11226 - 1993), so I am quite familiar with the vagaries of Van's plans set. What I have always done to "break the tie" among differing plans specs, is to evaluate them and then use the one that offers the most effective structural option - read "most rivets".

I am not familiar with any airframes built before the drawing set we have (11-25/28-1984), so I can't speak to the "correctness" of your build - but it wouldn't surprise me if yours was built according to the plans in effect at that time.

However, having said that, my plans don't show any revisions on DRG 23 that might indicate an earlier single row rivet pattern.

YMMV

HFS

Weak area

Just looked at both my RV-3's. Neither have the forward skin overlap and rivet line.

On the crashed RV-3, the forward skins tore of off the rivets. So one could consider this a weak area (longerons also sheared at that point). I my case it probably saved my skin because the forward part with the engine fuselage tank tore off and landed some 20 feet ahead and caught fire. I was left hanging uo-side-down in the harness with wings wrapped around trees.

Am I going to rebuild my flying RV-3B because of that? No.

I guess one could drill out the existing rivets, insert a skin strip and add the 2nd rivet line. But, drilling out the existing rivets could weaken the skins and bulkhead flange. I guess one could add a third rivet line behind the bulkhead.

Finn

Russell kindly pointed out that my bought aircraft only has one rivet line at the F-305 bulkhead, where it should have two. And that the rivets along the stiffeners on the rear fuse seemed to have the wrong spacing.

So I got out my plans, and am confused.

My plans set is dated 11-25-1984, and when I compare sheets 21 and 22 (forward and rear fuselage) against sheet 23 (Fuselage skins and rivets), things don't seem to add up. See attachments

(My plane seems to have been built according to sheets 21 and 22, by the way)

Anyone who can shed light on this one? Thanks!

P.S. I have been looking at photos of RV-3's and have found both versions to exist. Although the double rivet line with 1-1/4" rivet spacing seems to be in the majority. Zooming in on this photo though shows what seems to be a single rivet line, and 1" rivet spacing along the bottom edge of the aft fuselage. https://imgbb.com/VWBJb1R ( https://i.ibb.co/8D8NGCq/CCTG-and-MIRV.jpg)

Just looked at both my RV-3's. Neither have the forward skin overlap and rivet line.

On the crashed RV-3, the forward skins tore of off the rivets. So one could consider this a weak area (longerons also sheared at that point). I my case it probably saved my skin because the forward part with the engine fuselage tank tore off and landed some 20 feet ahead and caught fire. I was left hanging uo-side-down in the harness with wings wrapped around trees.

Am I going to rebuild my flying RV-3B because of that? No.

I guess one could drill out the existing rivets, insert a skin strip and add the 2nd rivet line. But, drilling out the existing rivets could weaken the skins and bulkhead flange. I guess one could add a third rivet line behind the bulkhead.

Finn

Lufthans

Well Known Member

Thanks guys.

So basically, my plane is not the result of a major F-up, but merely outdated. I can live with that.

So.... back it is to making all the systems work again, safely this time.

(And Finn, that sounds like a VERY scary story. Have you written it down somewhere?)

So basically, my plane is not the result of a major F-up, but merely outdated. I can live with that.

So.... back it is to making all the systems work again, safely this time.

(And Finn, that sounds like a VERY scary story. Have you written it down somewhere?)

RussellT

Well Known Member

Hans, this is interesting and I went back to look at mine in more detail. I have the preview only build manual drawings, the full size construction plans as well the USB version, all showing differences but essentially the same as what you found. The USB and builders manual preview show AN426 AD4-4 single line however that size rivet is not shown on the full size drawing #21 instead a notation to see #23 section A-A which then shows double row of AN 426 AD3 rivets. I used the section A-A full size detail on sheet #23 depiction for my build.

I would be curious to know if your plans show the details of section A-A on sheet #23 along with the note to see such on sheet #21?

Anyway I am sure yours is just fine as it is and I look forward to seeing you tidying it up.

Russell

I would be curious to know if your plans show the details of section A-A on sheet #23 along with the note to see such on sheet #21?

Anyway I am sure yours is just fine as it is and I look forward to seeing you tidying it up.

Russell

David Paule

Well Known Member

Here's the detail that Russell is referring to:

For the benefit of anyone following the thread and possibly having a different version of the plans. This was from my plans, dated 11-25-84. There is a revision incorporated, R1, dated 5/00, which did not affect this area.

Dave

For the benefit of anyone following the thread and possibly having a different version of the plans. This was from my plans, dated 11-25-84. There is a revision incorporated, R1, dated 5/00, which did not affect this area.

Dave

Lufthans

Well Known Member

Here's the detail that Russell is referring to:

For the benefit of anyone following the thread and possibly having a different version of the plans. This was from my plans, dated 11-25-84. There is a revision incorporated, R1, dated 5/00, which did not affect this area.

Dave

Yup, that's on my sheet 23 too. Mine are dated the same. Thing is, that my sheet 21 and 22 (of the same date) show only one row of rivets (and different rivet spacing in other areas). And my plane seems to have been built in accordance to these sheets 21 and 22, and thus in contradiction with sheet 23. My question was basically: was the builder a renegade moron who cut corners? Answer: no, he just stuck to sheets 21 and 22 (or perhaps an older version of the plans).

I don't feel the need to rebuild half of my fuselage now. There are more aircraft flying around with a single row of rivets there, and they are not falling out of the sky left and right.

Still, it is interesting how conflicting versions of something this fundamental have found their way in the same set of drawings, dated on the same day.

David Paule

Well Known Member

The front area of the seat pan has integral steps. On my plane I misinterpreted that detail and cut the seat pan so that the steps are separate pieces. (EDIT - the steps are supposed to be separate, see other postings below, so I accidentally got it right!) This is the area on Dwg 24 that shows this.

The drawing indicates that the spar bulkhead flange goes from side to side. It doesn't, at least on the RV-3B. Here's that area on my plane. The photo was taken prior to adding the steps.

On both pictures, forward is to the left and top is the right side of the plane.

Incidentally, the rudder cable runs directly over the forward outboard screw on the steps. Bit of a pain there.

Just something to be aware of so that you don't need separate parts for the steps.

The drawing indicates that the spar bulkhead flange goes from side to side. It doesn't, at least on the RV-3B. Here's that area on my plane. The photo was taken prior to adding the steps.

On both pictures, forward is to the left and top is the right side of the plane.

Incidentally, the rudder cable runs directly over the forward outboard screw on the steps. Bit of a pain there.

Just something to be aware of so that you don't need separate parts for the steps.

Last edited:

RussellT

Well Known Member

Dave, I think the steps are separate, my interpretation of the plans is that the seat pan is 025 2024-T3 and fixed with LP 4-3 pulled rivets and the steps are 062 6061-T3 with 3/4x3/4x1/8 angle supports. The steps are fixed with screws and nut plates, 10 per side removable.

At least that's how I did mine, I could be wrong...

At least that's how I did mine, I could be wrong...

I don’t think there are any two -3’s alike in this area - I built a two-piece close out that covers most of the stick opening and also provides the steps.

David Paule

Well Known Member

Manual Trim Cable Routing

It seems as if the manual trim cable should enter the cockpit above the rudder cable. That wasn't obvious to me and I arranged to have it enter below. Now things are clearer. My fuselage is slightly lighter with some additional cable holes in the seat and baggage bulkheads.

Keep the manual trim cable above the rudder cable.

Dave

It seems as if the manual trim cable should enter the cockpit above the rudder cable. That wasn't obvious to me and I arranged to have it enter below. Now things are clearer. My fuselage is slightly lighter with some additional cable holes in the seat and baggage bulkheads.

Keep the manual trim cable above the rudder cable.

Dave

David Paule

Well Known Member

Control Mixer

I was happily bolting in the control stick and mixer assembly when I noticed that the mixer's lug fittings that connect to the elevator pushrod fitting were binding. The radius of the welded mixer fitting was too large. Have a look on Dwg 27 on the left side. Here's a look at the area of concern; up top in Section B-B' you can see the assembly.

The as-supplied radius is 1/2". I reduced it to 3/8" to clear, with plenty of edge distance remaining. It's only the aft end of the part that interferes, so I suppose an alternate (and slightly heavier) method of getting clearance at the rod-end fitting would be to simply bend the tips of the welded part out a bit.

Dave

I was happily bolting in the control stick and mixer assembly when I noticed that the mixer's lug fittings that connect to the elevator pushrod fitting were binding. The radius of the welded mixer fitting was too large. Have a look on Dwg 27 on the left side. Here's a look at the area of concern; up top in Section B-B' you can see the assembly.

The as-supplied radius is 1/2". I reduced it to 3/8" to clear, with plenty of edge distance remaining. It's only the aft end of the part that interferes, so I suppose an alternate (and slightly heavier) method of getting clearance at the rod-end fitting would be to simply bend the tips of the welded part out a bit.

Dave