A & B Curve Clarification

The following is to help you understand how the P-mags work. I will not comment on the actual Emag timing map as that is considered proprietary to Emag Ignitions and due to our relationship with them we promised that we would not publish their timing map/curve. What Brian has documented is the MAP's contribution to the timing curve. As you can imagine, those numbers are not always used to calculate the firing angle. In Brian's defense, the numbers he published at the start of this thread are what is reported by Emags EICAD program.

The P-mag has, in effect, two memory locations, A & B. Commonly called the “A Curve” and “B Curve”.

To switch between the two, a builder installs a jumper between pins #2 & #3 on the P-mag. The default, no jumper installed, is to run on the B Curve. Once the jumper is installed, the Pmags switch to the A curve. (When our EICommander is installed, no jumper is required. I will explain that later.)

The B Curve is fully configurable via Emag’s EICAD program or our EICommander. This discussion assumes an unmodified B Curve.

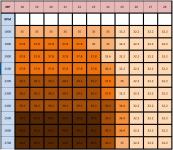

The A Curve, jumper installed, starts the timing at around 26* BTC and will allow the timing to advance up to 34* BTC, depending on RPM and MAP.

The B Curve, jumper

NOT installed, adds a five degree shift to the A Curve. Thus timing starts at around 31* BTC and advances up to 39* BTC.

That is all in the

Pmag manual, page 14 and mimics what we have found on our test stand and in actual flight conditions.

The pilot has the ability to adjust the max advance and the advance shift via the EICAD program or the EICommander. For example, if your engine requires a timing of 20*BTC, then you can enter in a negative shift and reduce the timing to 20* BTC and the max advance will also be reduced.

With this in mind, it should not surprise anyone who has read the manual that when operating with the B Curve (No jumper installed) under high power settings, such as during takeoffs, that the Pmag sets the timing at 31* BTC. With the jumper installed, the Pmag will set the takeoff timing to 26* BTC.

During the development of the EICommander, we took an old engine and cut the case in half and used that to spin two Pmags on our test bench. We discovered that there is so much gear slop in our drive trains that even standard magnetos vary by as much as 1.5*. This is really noticeable when running a light, composite propeller.

The idea of setting the timing one or two degrees after top dead (TDC) center is suggested by Emag for those who run composite propellers so the spark fires after the prop has crested TDC and the spark helps spin the prop. This may be necessary because when below 200 RPM’s the Pmags fire at TDC, not after TDC, and a light prop may not have the inertia to get past the compression stroke and spark plug firing when starting. Metal props don’t seem to have this problem. (For the record, I run the A curve and my TDC is set at zero for my O-360 with a Catto prop.)

EICommander

The EICommander that we produce is simply a piggy back unit for the Pmags. It can monitor the Pmags and display the current advance numbers (not the MAP contribution), along with any divergence in timing between two Pmags, the condition of the ignition harnesses and a number of other parameters.

When first installing an EICommander, the Pmags will automatically default to the B Curve. Thus, we recommend our clients send the P-mags the A Curve, if they want to run the A Curve. (New engines, or newly rebuilt engines should run the A curve for the first 10 to 15 hours and cap the advance to 26* BTC either via a custom EICommander configuration or by plugging the MAP lines to the Pmags.)

We tell clients to think of the Pmag as having two memory locations, A & B. The A location is fixed and cannot be changed. The B location is fully programmable and when the EICommander sends the A configuration to the P-mags it is actually stored in the B memory location. Thus, the A & B configurations are exactly the same at this point but because there is no jumper installed (or required), the Pmags will act like they are running the A Curve.

Should a client wish to create a custom “C” configuration (Say with a 20* BTC starting point), they simply send that to the Pmags and it will be stored in the “B” memory location. In other words, with the EICommander installed, the Pmag never use the “A” memory location, regardless of what configuration is sent the Pmags.