Hi Derek,Hi Martin,

thanks for the nice write-up. I love this group. Every plane is a bit different and what you did makes perfect sense.

You can question this decision but my engine depends on electricity. If I can cover one more remote case that would help, I'll not pass on that option.

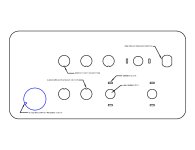

I am putting in two EarthX batteries that can deliver a lot of current and they have all sorts of internal supervision and if something is violated, they shut off. I am therefore afraid of activating the cross bar / bus tie should one battery be low and the other full. The last thing I want to do is tripping the good battery by switching the bad one in parallel. Anyway, that was my thinking, I want to turn one battery off before activating the cross bar but I may want to use the alternator of that side. Just a very remote case.

Thanks for sharing your overvoltage thoughts, very helpful, I'll check that on my side.

/Martin