Saville

Well Known Member

Andair Fuel Valve Replacement Installation - Design

I have a LEFT - BOTH - RIGHT - OFF Andair Fuel Valve installed in my -8.

Given that I have a new left tank being built I decided to replace that with an Andair LEFT - RIGHT - OFF.

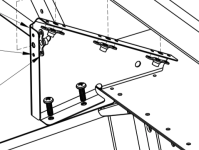

The present installation is beyond hideous. Extremely difficult to remove the panel to look down there and/or tighten the B-nuts.

Here it is:

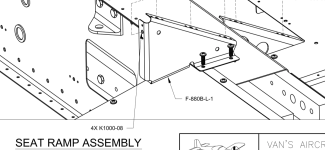

I notice in the plans that if you have the Van's valve you install it using bracket F-883A:

Here is Detail A on the plans:

But Andair Valves won't fit inside the bracket. Something else has to be done.

I have 2 ideas:

1) Make a new bracket, using the same thickness material, that is wide enough so that the Andair valve can fit. Rivet that to the flanges. It would be hard to get in there and rivet new support cross member to the flange that's riveted to the skin.

2) Make a new cover plate out of 0.064 sheet aluminum and mount the Andair directly to that using nutplates.

Any ideas wold be welcome. Especially if you've retro-fitted an Andair valve to an already built airplane.

Yes I know the wires have to be gotten out of the way.

Thanks !

I have a LEFT - BOTH - RIGHT - OFF Andair Fuel Valve installed in my -8.

Given that I have a new left tank being built I decided to replace that with an Andair LEFT - RIGHT - OFF.

The present installation is beyond hideous. Extremely difficult to remove the panel to look down there and/or tighten the B-nuts.

Here it is:

I notice in the plans that if you have the Van's valve you install it using bracket F-883A:

Here is Detail A on the plans:

But Andair Valves won't fit inside the bracket. Something else has to be done.

I have 2 ideas:

1) Make a new bracket, using the same thickness material, that is wide enough so that the Andair valve can fit. Rivet that to the flanges. It would be hard to get in there and rivet new support cross member to the flange that's riveted to the skin.

2) Make a new cover plate out of 0.064 sheet aluminum and mount the Andair directly to that using nutplates.

Any ideas wold be welcome. Especially if you've retro-fitted an Andair valve to an already built airplane.

Yes I know the wires have to be gotten out of the way.

Thanks !

Last edited: