Mikeandmaz

Active Member

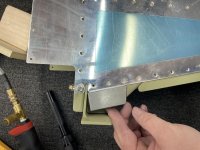

On page 7:10; Step 4, the instructions say rivet the aft 8 holes common to the Bottom rib, Rudder Skin Assembly, and Attach Strip. Fig 1, on the same page shows the rivets to be completed leaving the last hole before the TE open. Did that.

Step 3 rivets the Bottom ribs together, this I?ve also done.

But now it would seem impossible to rivet that last hole left open in Step 2 as there is hardly room to get the rivet in let alone a bucking bar.

Any ideas? Apart from drilling out the blind rivets holding the two bottom ribs together.

Thanks in advance.

Mike

Step 3 rivets the Bottom ribs together, this I?ve also done.

But now it would seem impossible to rivet that last hole left open in Step 2 as there is hardly room to get the rivet in let alone a bucking bar.

Any ideas? Apart from drilling out the blind rivets holding the two bottom ribs together.

Thanks in advance.

Mike