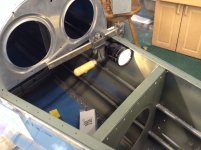

Another 30 minutes in the shop Friday, and I had the right front spar out of the horizontal stabilizer, completing the first "R" in this R&R project. That blinding light in the upper left of the photo below is sunshine streaming through an open hangar door, something we've seen precious little of around here this year...

Saturday, while awaiting delivery of new parts for the HS, I spent several hours finishing up steel flap pushrods to replace the aluminum ones I wasn't particularly happy with (threads too loose on at least one). After tapping these new ones, I now have a better appreciation on just how tough 4130 really is. I used the same setup I used with the aluminum tubes, removing the handle and cone from my RoloFlare tool and squarely but loosely mounting it on my drill press to make it self-centering, but with the steel, I could only get about 2-3 full turns or so with the tap (drive belts removed, turning the chuck by hand), and had to clamp the flaring tool with tube and tap in the bench vice, and turn the tap with a wrench. I had to break chips about every 1/4 turn, so it was quite a tedious process, but well worth it IMHO.

As expected, I received the repair parts for my horizontal stabilizer Saturday afternoon, as well as a flash drive containing the RV-7 manual and plans. Vans even cut the HS-00001-1 spar doublers in two for me so everything would fit in a 5-inch diameter mailing tube!

After inventorying the parts, I printed out the pertinent pages of the manual and sections of DWG 3 that differ from the original plans and drawing, but didn't have time to get started.

After a breakfast flight this morning with 5 airplanes and 7 folks from Brighton (including an RV-6A and my 170), I spent about 4 hours in the hangar cleaning up about 6 months of disorganization and saying "I'll get to that later". (Check the workbench in the background of the first photo in this post.

) I even found several items that I forgot I owned, including a fire extinguisher, which I promptly mounted. I now have my workbench to the point that there's room for working on the stabilizer repair.

Just about the time I got the new stabilizer parts laid out on the freshly cleaned bench, neighbors noticed the hangar door open and started showing up, so the beer light went on. Of the three that showed up, two had also been spring cleaning in their own shops, and the third had spent the day on some long-delayed exterior maintenance on the airport clubhouse. I was glad to point each one of them to the fresh pint glasses on the kegerator (currently Killian's Irish Red)... they had earned it!

No shop time logged today, as I have a 8-hour bottle to tool rule...