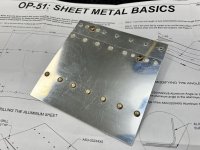

We recently made a small addition to every RV tail/empennage kit we ship. We’re now including our OP-51 “Sheet Metal Basics” kit, a small and practical learning exercise that folks can use to practice/develop their skills before jumping into building the actual tail kit. It certainly doesn’t replace our more advanced practice kits like the toolbox, lightbox sign or practice airfoil. In other words, this one ain’t meant to be purdy – It’s practical! Think of it as an extra opportunity to try things before you jump in, if desired. It’s especially good to use for practice in *fixing* mistakes – something we all need to feel confident in. Worried about drilling out and replacing rivets for the first time? Use this little kit to practice and don’t worry about messing it up while you’re learning. We’ve used the “Sheet Metal Basics” kit with STEM educational programs for many years to help kids learn the basic skills, too.

Included is an instruction sheet, aluminum sheet pieces and angle, plus the necessary hardware – the same sort of hardware that is commonly used in building our aircraft kits.

Don't need it? Cool! Use it to teach a kid from your neighborhood how to use the tools and build skills. And be sure to post or send us a photo of you teaching them! Spread the opportunity and help construct the next generation of builders!

You don't have to order a tail kit to get it, by the way. I mean, we certainly would like it if you did. But, if you already have your tail kit it's also available to order online at our web store for the princely sum of $10 plus shipping. You can search for "BAG SHEET METAL BASIC" to find it.

And since history tells us that someone will comment or ask: No, we didn't increase the tail kit prices because of this.

Included is an instruction sheet, aluminum sheet pieces and angle, plus the necessary hardware – the same sort of hardware that is commonly used in building our aircraft kits.

Don't need it? Cool! Use it to teach a kid from your neighborhood how to use the tools and build skills. And be sure to post or send us a photo of you teaching them! Spread the opportunity and help construct the next generation of builders!

You don't have to order a tail kit to get it, by the way. I mean, we certainly would like it if you did. But, if you already have your tail kit it's also available to order online at our web store for the princely sum of $10 plus shipping. You can search for "BAG SHEET METAL BASIC" to find it.

And since history tells us that someone will comment or ask: No, we didn't increase the tail kit prices because of this.

Last edited: